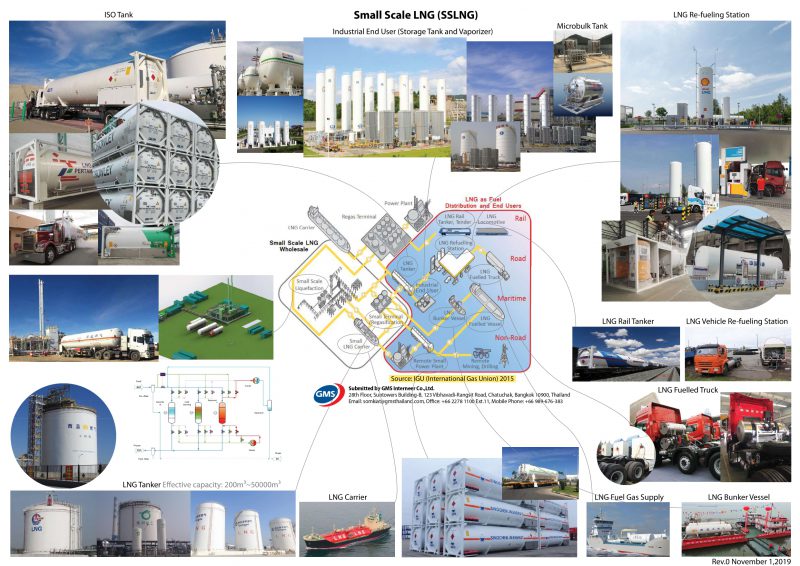

LNG equipments

LNG as Fuel is one of the important parts in LNG industries.To provide effective transportation across the world

LNG equipments we offer the highest standard and application for our cusotmers.There are many types of Small Scale LNG equipment such as LNG transportation , Cryogenic Liquid Semi-trailer ,LNG Station LNG storage tank for Permanent LNG station,LNG as truck fuel, LNG Vehicle gas Supply System

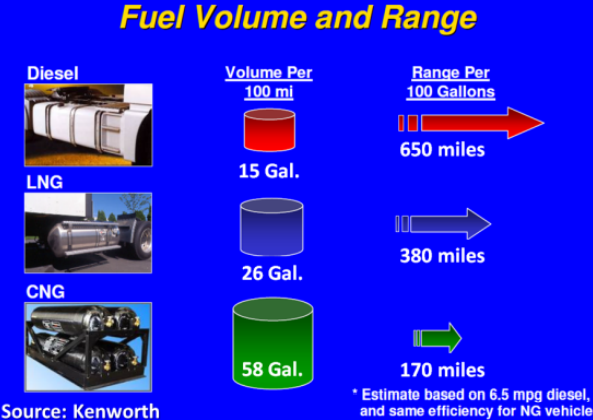

Vehicle Range

The widespread use of gasoline and diesel is largely explained by energy density and ease of onboard storage. The energy per unit volume is a key determinate to the distance a vehicle can travel before needing to be refueled. LNG has lower energy density per unit volume than diesel and therefore has a lower range than diesel, but higher range than CNG. A comparison of fuel volume and range for diesel, LNG and CNG is given in Figure 18.

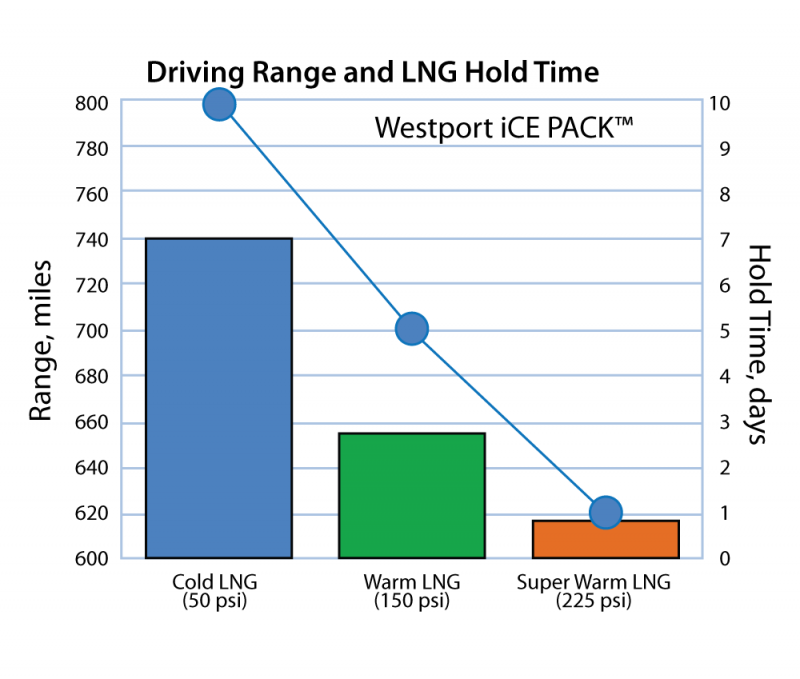

The density of LNG, and therefore the amount of energy in the equivalent volume of fuel, is related to the temperature and pressure in the tank. LNG at lower temperature and pressure will provide an increased range for the vehicle and a longer hold time in the fuel tank34 . For example, a truck fueled with LNG at 50 pounds per square inch gauge (psig) has range up to 740 miles and a hold time up to 10 days, compared to a super warm tank of LNG at 225 psig, which has a range up to 620 miles and one day hold time, Figure 19.

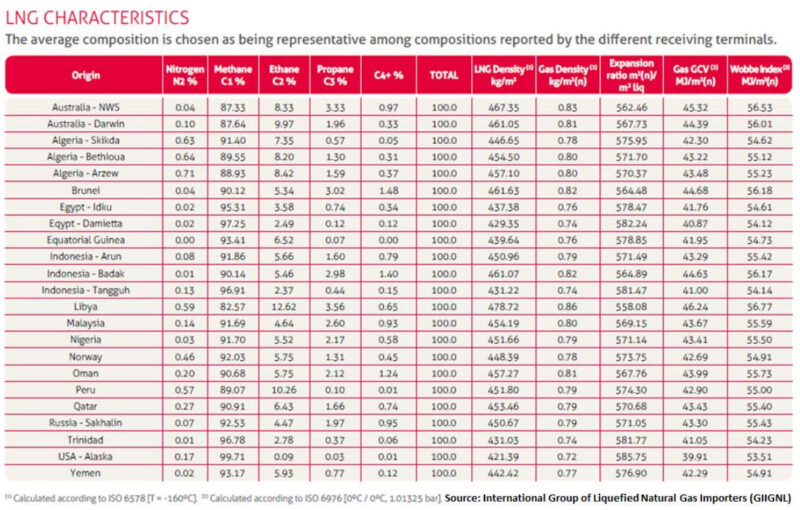

LNG Quality

Variations in LNG quality could cause inefficiencies and equipment performance issues for the end user. Although a number of guidelines exist for fuel composition for natural gas engines, there are few standards in existence. The principal constituent of natural gas is methane (CH4) with smaller quantities of other components including heavier HC, hydrogen sulfide (H2S) and inerts (e.g. CO2 and nitrogen (N)). The natural gas is treated to remove impurities and gas liquids, then liquefied through a refrigeration process to approximately -260˚F (-162˚C) to yield LNG. Typically LNG consists of 83% to 97% CH4 with small amounts of ethane (C2H6), propane (C3H8), butanes (C4H10) and trace amounts of nitrogen gas (N2). The design of the liquefaction plant, usually based on the specification required by the end user, will determine the composition and quality of LNG produced. LNG quality therefore varies depending on the source of the LNG (i.e. which liquefaction plant it is produced by), as well as transportation time, during which the composition can change slightly due to the evaporation or boil off of lighter components. LNG quality is typically described using a measure of energy content (e.g. gross calorific value), the combustion characteristics of the LNG (e.g. Wobbe Number, Soot Index, or Incomplete Combustion Factor) and the impurities contained in the LNG (e.g. % sulphur, CO2, N2). Gross heating value is a key measure of LNG quality since LNG is sold on an energy basis. The range of gross heating value (and other key quality parameters) for a variety of different sources of LNG is given in Figure 20, showing a range of 39.92 MJ/m3 to 46.24MJ/m3 . Further information is given in Appendix 9.h, LNG Quality and Methane Number