Welpsun Pipeline Steel pipe

We’re a team of nearly 4,000+ people across the world, focused on building a ulture of ‘Engineering Excellence’in our Welpsun Pipeline

Over the last two decades, our innovative approach and, technical capabilities have helped us deliver some of the path-breaking Welpsun Pipeline projects across the world.

With over $1.2 billion of annual revenue, Welspun Corp is a true Indian multinational, operating across multiple geographies. We share a close relationship with our customers, and are the providers of choice for some of the largest players in the global oil and gas industry.

Welpsun Pipeline Capacitied and Capabilities

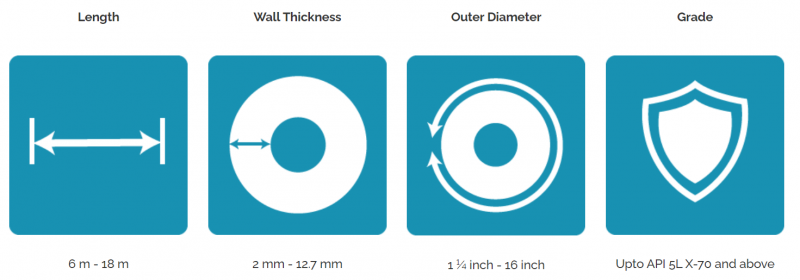

ERW

Anjar: 150,000 MTPA

Technical Excellence

- 90 m long Looper Tunnel/ Accumulator with 180 meters strip length capacity

- 600 kW solid state High Frequency Welder with on-line monitoring and data recording

- 1500 kW Seam Normalizing Unit comprising 3×500 kW Induction Units

- On-line Internal Bead Scarfing with CCTV monitoring

- State-of-the-art ROTO UT System (Immersion Testing) for Weld, HAZ and Pipe Body (100% coverage)

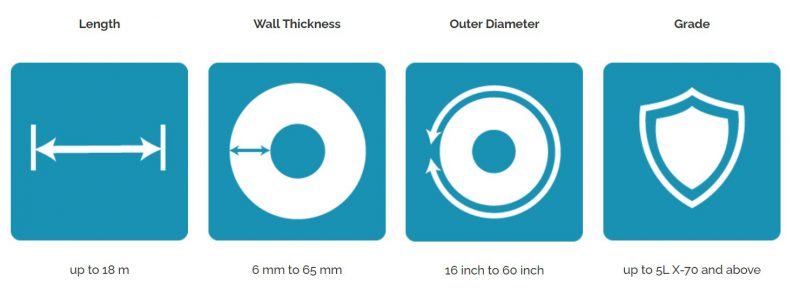

LONGITUDINAL SUBMERGED ARC WELDED (LSAW)

Dahej: 350,000 MTPA

Anjar: 350,000 MTPA

Technnological Excellence

- High thickness rolling capabilities

- Auto Pipe Dimension Measurement System (APDMS)

- Online Plate UT System

- State-of the-art, high capacity, PLC governed Mechanical Expander

- High capacity (650 bar) Hydro Testing Machine

- State-of-the-art Auto UT from GE Inspection Technology (2 lines)

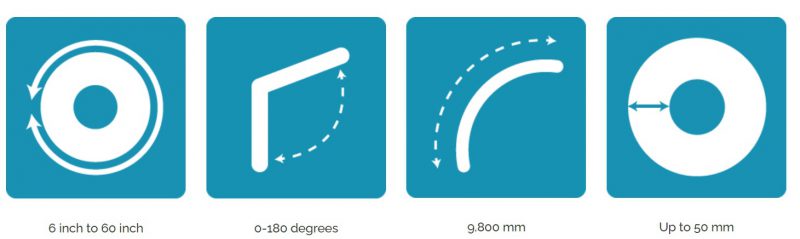

HELICALLY SUBMERGED ARC WELDED (H-SAW)

Anjar: 380,000 MTPA

Dahej: 50,000 MTPA

Mandya: 150,000 MTPA

Bhopal: 175,000 MTPA

Technological Excellence

- 240 meters long, Non-stop Coil Feeding Line with on-line Transverse Milling and Flying Cross Seam Welding System

- Max Coil Width: 2,800 mm for high productivity

- Heavy duty, 45 MT capacity De-coiler

- Digital pulse GMAW Welding System equipped with Automatic Lase Control for spatter free welding

- Hight definition, Digital Control Power Wave SAW System with 3-axis Laser Seam Tracking

BENDS

Anjar, India: Hot Pulled Induction Bends, 39000 Number of Bends

Tecnological Excellence

- In-house Mother Pipe manufacturin

- Controleed alloy design from steel making stage for mother pipes

- 500 kW and 1500 kW Induction Heating capacity

- Minimum wall thining and oveality

- Precise bending redius and angle

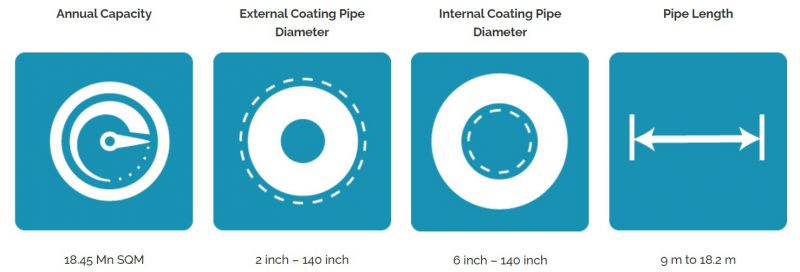

COATING

Anjar: 13.45 million sq. m

Dahej: 5 million sq. m.

Tecnological Excellence

- Concrete Coating Capability for length up to 18 meters – 2nd in the world.

- Continuous OD measurement monitoring

- Automatic wire attaching and cutting system (currently on design stage and will be installed soon)

- Fog cure system to achieve faster and better strength

- Completely enclosed CWC Plant to coat in all weather condition

- Anode gap filling by Polyurethane Foam or Mapei Grout

Welpsun Pipeline Standard

1.Pipe

Specification/ Grade

API 5L/ ISO 3183 (Grade up to X80/ L550), API2B, DNV-OS-F101,ASTM, EN10208

2.External and Internal Pipe Coating

Coating Product Range

- 3 Layer Polyethylene / Polypropylene Coating.

Complying ISO 21809-1, DIN 30670-12, DIN 30678-13, CSA Z.245.21-Series-14, NF49 710, NF49 711 and Client Specification

- Fusion Bonded Epoxy (Single / Dual layer) coating.

Complying CSA Z 245.20 Series -14, NACE SP 0394-13, ISO 21809-2 and Client Specification

- Internal Flow Epoxy Coating.

Complying API RP5L 2, ISO 15741 and AWWA C210

- External and Internal Bend Coating.

Complying EN 10290, API RP5L 2, ISO 15741 , AWWA C210 and Client Specification

- Concrete Weight Coating

Complying ISO 21809-5, AWWA C 205, DNV-OS-F101 and Client Specification

Anjar Manufacturing Plant & Dahej Manufacturing Plant

Anjar Manufacturing Plant

Key Highlights

- Spread over a total area of c.1,000 acres

- Captive power capacity of 159 MW

- Approved by Lloyd’s Register Quality Assurance for Environmental and Safety standards – ISO 14001:2004 and OHSAS 18001:2007

- SA 8000

- International Safety Award 201

Dahej Manufacturing Plant

Key Highlights

- Spread over an area of c.100 acres

- Captive power capacity of 6 MW

- Approved by Lloyd’s Register Quality Assurance for Environmental and Safety standards – ISO 14001:2004 and OHSAS 18001:2007

- SA 8000

- Awards: National Safety Award 2015

Project Reference

Client Recognition

- Preferred vendor to 50+ Oil & Gas companies globally enhancing ability to participate in bids of key projects

- Accredited for both, products and plant facilities, from global oil & gas majors requiring stringent specifications and quality requirements

- Superior capabilities resulting in being a sole supplier to qualify the specifications and quality tests

- Historically, enjoyed long term frame agreement with 3 marquee oil & gas clients

- Local presence in major markets provides ability to quickly adapt to customer requirements

- Leading supplier to key water projects across Saudi Arabia and India

Award

Brochure

Download