Overview – EPCON Dual Compact Flotation Unit (CFU)

-

Enhanced produced water treatment efficiency with a 50% smaller footprint

The EPCON Dual compact flotation unit (CFU) has a unique internal design that incorporates residual flotation gas in a secondary separation stage to increase oil-in-water (OIW) removal while fully degassing the clean water outlet. The compact, simple system achieves optimal water treatment in half the footprint of conventional technologies, saving rig space and streamlining operations—all with no moving parts.

-

Testing and simulation leads to real-world results

Computational fluid dynamics simulation, onshore pilot testing, and offshore results verification guided and validated the design of the EPCON Dual CFU. A successful field trial was performed on a Statoil installation in the Norwegian waters of the North Sea. Posttreatment outlet oil concentration was measured at 10 ppm, down from pretreatment levels in excess of 25 ppm. The results also verified 27% better separation rates compared with conventional technologies.

-

Special features :

- Better performance – Significantly improved oil removal and degassing in a 50% smaller footprint than conventional systems

- Less costs – No bulk storage, transportation, or shipping to onshore facilities

- Environmental consciousness – Minimized environmental impact

- Long life – Robust construction and extended operating life

Application of EPCON Dual Compact Flotation Unit (CFU)

The treatment of produced water using gas flotation relies on the principle that if a gas bubble attaches itself to an oil droplet, the resulting increase in buoyancy will promote a faster separation to the liquid surface due to its enhanced settling velocity. The gas bubbles are normally created from two sources – dissolved gas and induced gas with static mixer at inlet of EPCON CFU. Dissolved gas evolves due to the pressure drop across the upstream deoiling hydrocyclone and/or the production separator water level control valve. The inlet water to the EPCON CFU technology is introduced tangentially into the vessel to induce a velocity swirl. This swirl, with the aid of carefully optimized internal devices, cause gas bubbles and oil droplets to be driven towards the center of the vessel.

This creates a radial oil concentration gradient whichcomplements the axial oil concentration gradient induced by gravity to produce a peak oilconcentration in the upper center region of the EPCON CFU vessel. The treated water exits at the bottom of the vessel. As the oil surface is forced towards the center of the vessel and collected together with the gas, both will flow through the primary reject line.

The lower part, in a separate stage, will utilize associated gas and a secondly generated swirl to extract residual oil and gas in a counter-current flow through a secondary reject.

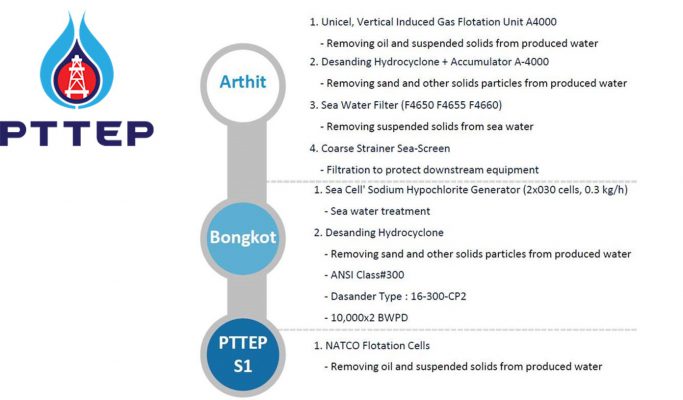

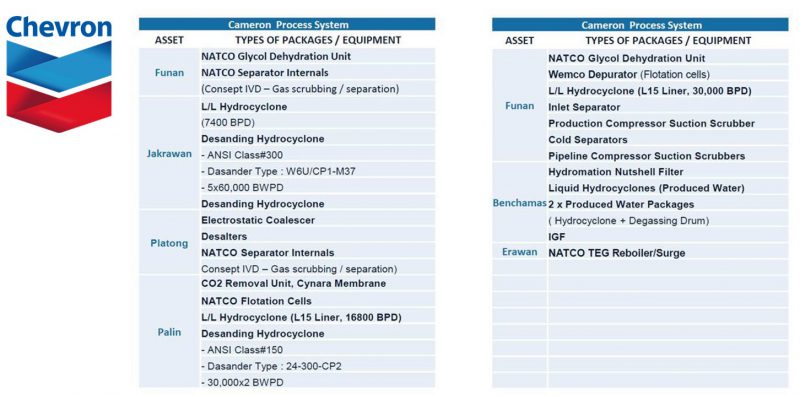

Project Reference

Brochure

Download