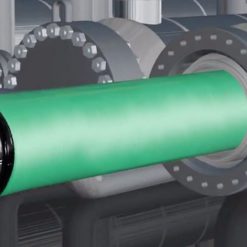

Overview – Cyclotech B Series Deoiling hydrocyclone

Balancing efficiency and throughput capacity in a reliable, wear-resistant separation solution

Deoiling hydrocyclone technologies represent the state of the art in produced water treatment, optimizing the critical balance between oil-removal efficiency and throughput capacity. Achieving this balance yields peak separation in the most cost-effective and space-efficient manner. These technologies have a global track record in onshore and offshore facilities.

Having no moving parts, CYCLOTECH B Series hydrocyclone technologies achieve liquid-liquid separation using a pressure drop across the unit. Their liners are manufactured from a range of wear-resistant materials, including tungsten carbide or reaction-bonded silicon carbide. An advanced ceramic that extends wear life up to 10 times beyond a standard duplex stainless steel liner is also available.

B Series technologies treat waterstreams containing up to 2,000 mg/L of oil to meet a discharge-water oil content of 30 mg/L—or more commonly, stretch targets as low as 15 mg/L.

With special features

- Improved reliability – Use of no moving parts and wear-resistant materials

- Smaller footprint – Compact design uses less space

- More efficiency – Retrofit capability increases capacity and separation performance

Application of Cyclotech B Series Deoiling hydrocyclone

Operating with no moving parts, B Series technologies achieve liquid-liquid separation using a pressure drop across the unit. Oily water is forced under pressure into the inlet section of the liner via a tangential inlet port. This pressure, together with narrow cyclone diameter, causes the fluid to spin at high velocity, creating a high gradial acceleration field. Oil, the less-dense liquid, is forced to the axial center of the hydrocyclone to form a thin oil core. Through internal hydrodynamic forces and external differential pressure control, this oil core is removed via the reject ports of the hydrocyclone liners; the clean water flow is discharged from the cyclone underflow.

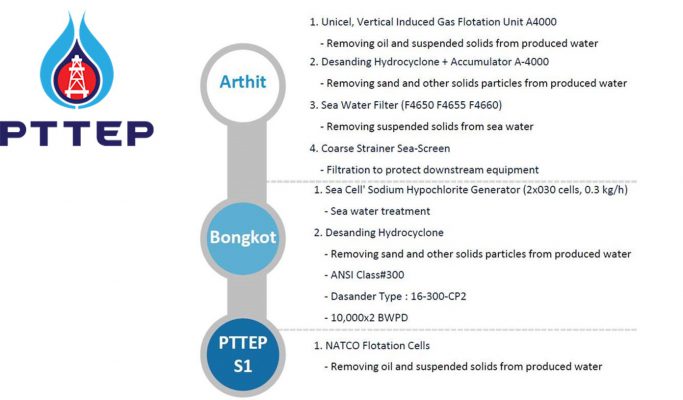

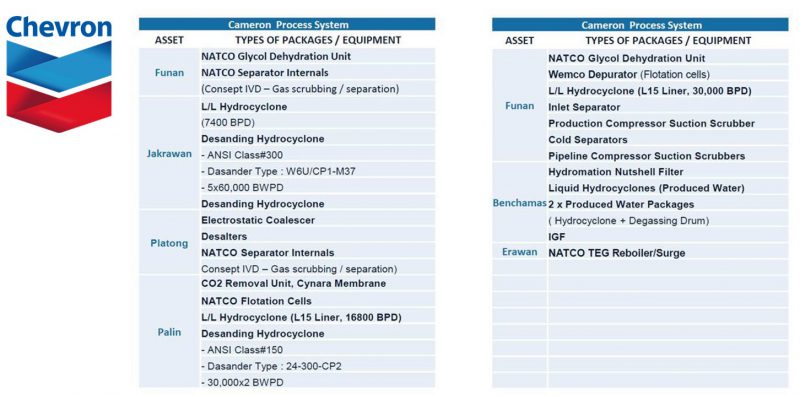

Project Reference

Brochure

Download