Overview – CYCLOTECH SCARPA Cyclonic separation technologies

CYCLOTECH SCARPA Cyclonic separation technologies is one of the most important machines.Whether produced from the reservoir or introduced through well servicing, produced solids are a growing concern for upstream operators. If left uncontrolled, solids production can cause major flow assurance issues.

The keys to successful topside sand handling is flexibility in process design, technology selection, and location. Sand production is unpredictable, and the management solution is never universal. Sand management almost always includes factors such as accumulation, fluidization, transportation, cleaning, and disposal—all of which require careful consideration.

Our sand management technologies and sophisticated process design methodologies provide you with the tools to optimize sand management for every application, including multiphase, in-separator and liquid phase.

-

Sand receiving and cleaning systems

We offer a range of CYCLOTECH separation technologies that clean sand to such low oil concentrations that the cleaned material can be pretreated prior to shipment to shore or reinjected into the reservoir.

-

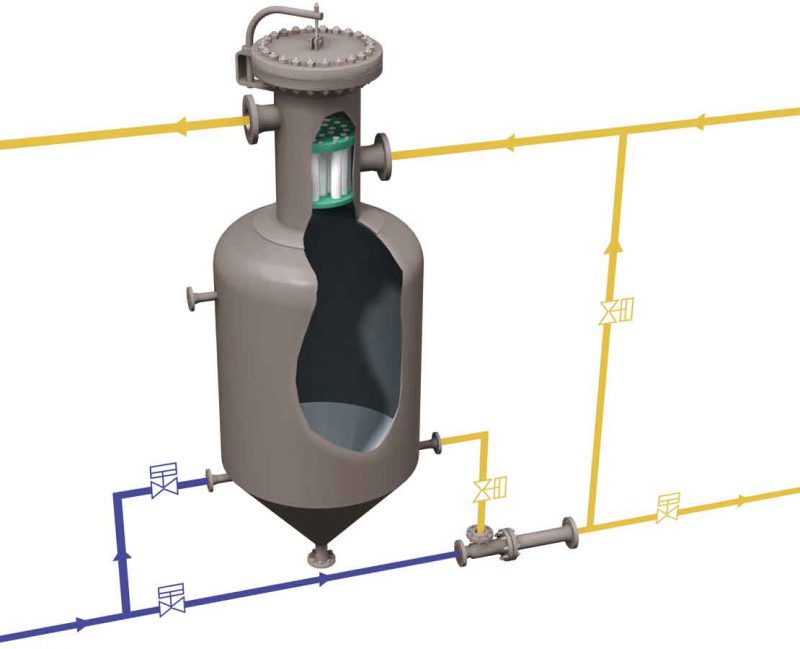

CYCLOTECH SCARPA eductive sand jetting system

CYCLOTECH SCARPA eductive sand jetting system is a sand-conveying and -removing apparatus that removes sand and other solids from a production separator on a continuous or batch basis. The modular system can be used to retrofit existing separators or incorporated into new-build plants.

-

Advantages

- Decreases pumped flow rate requirement

- Produces no effect on oil-water separation performance

- Maximizes separator water pad residence time

- Eliminates sand carryover to water and oil outlet streams

- Limits residue sand to less than 5% of total

- Reduces potential erosion and corrosion of separator

- Eases sand removal as it has less time to solidify in place

- Minimizes and controls sand concentrations in outlet pipe work, optimizing the availability and performance of downstream sand-handling equipment

- Limits the size and complexity of the downstream receiving equipment

- Minimizes risk of blockage

Application of CYCLOTECH SCARPA Cyclonic separation technologies

The SCARPA system creates a low-velocity flow that runs along the bottom of the separator through the use of specialized eductor nozzles. An eductor is an established solids-conveyance device that uses a small flow of high-pressure motive fluid to pump a higher-flow, lower-pressure fluid. The eductors’ format of suction from behind and discharge in front enables hydraulic balancing to generate a dynamic layer of water of comparatively low velocity along the bottom of a separator. Such hydraulic balancing prevents sand from settling and acts as an effective solids-transport system with minimal radial (vertical) disturbance.

This hydraulic conveyor can be directed toward one or more discharge outlet nozzles at the bottom of the separator and then routed to the suction of an external CYCLOTECH Sandscape* solids conveyance and concentration control system, which controls ejection of solids from the separator.

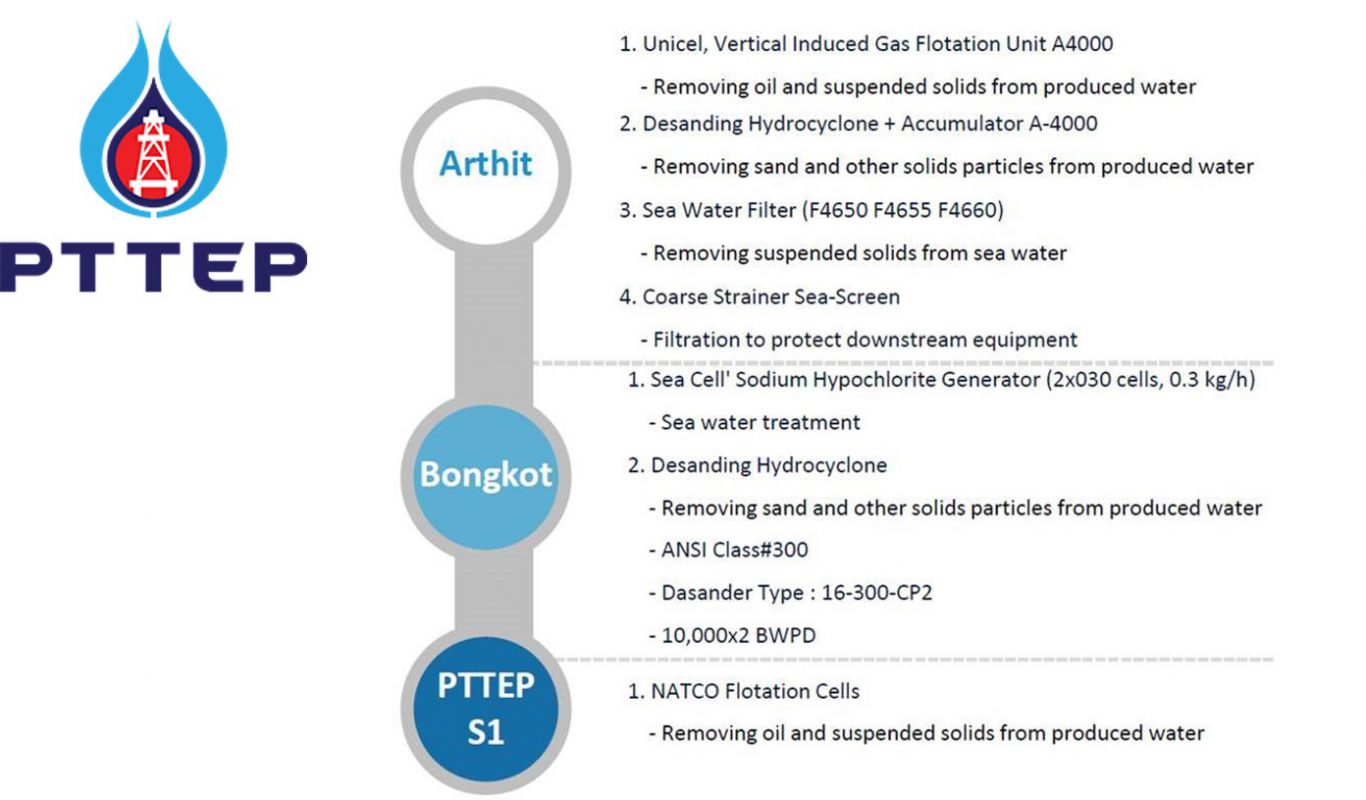

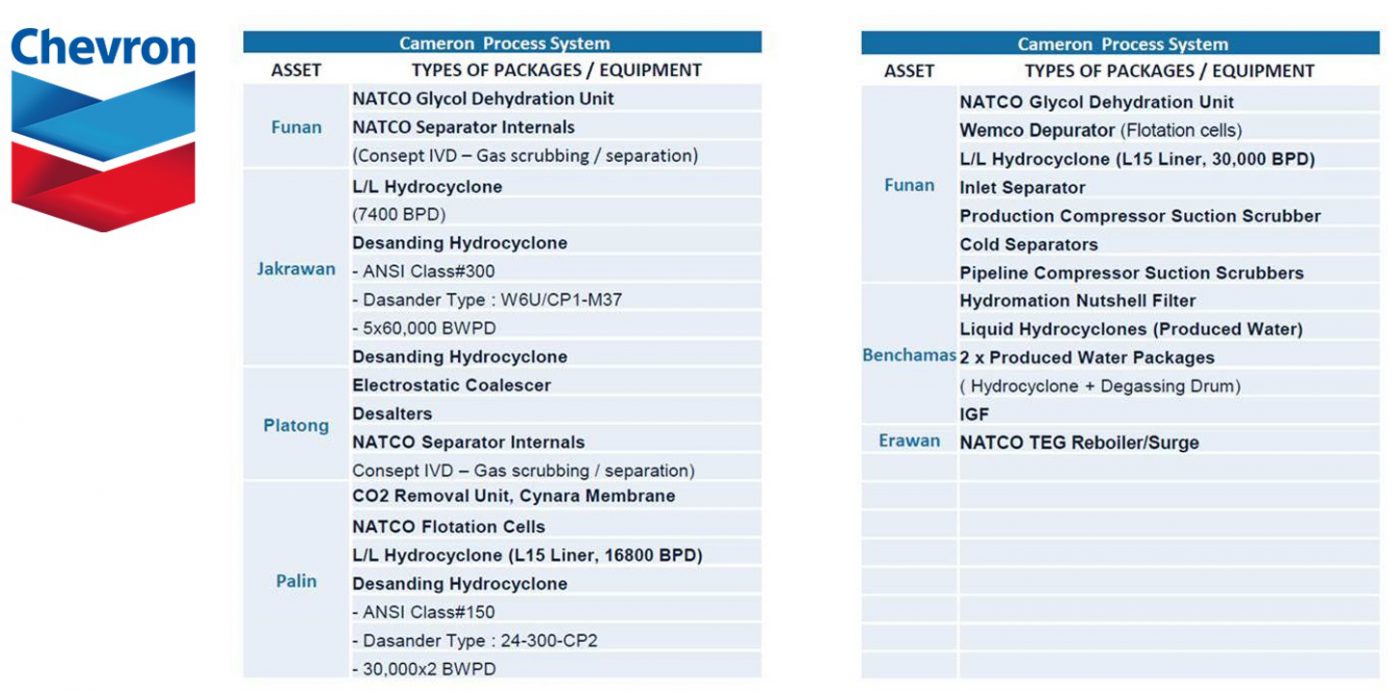

Project Reference

Brochure

Download