Overview – SEA-SCREEN Coarse Strainer

-

Reliable filtration of particles as small as 25 um

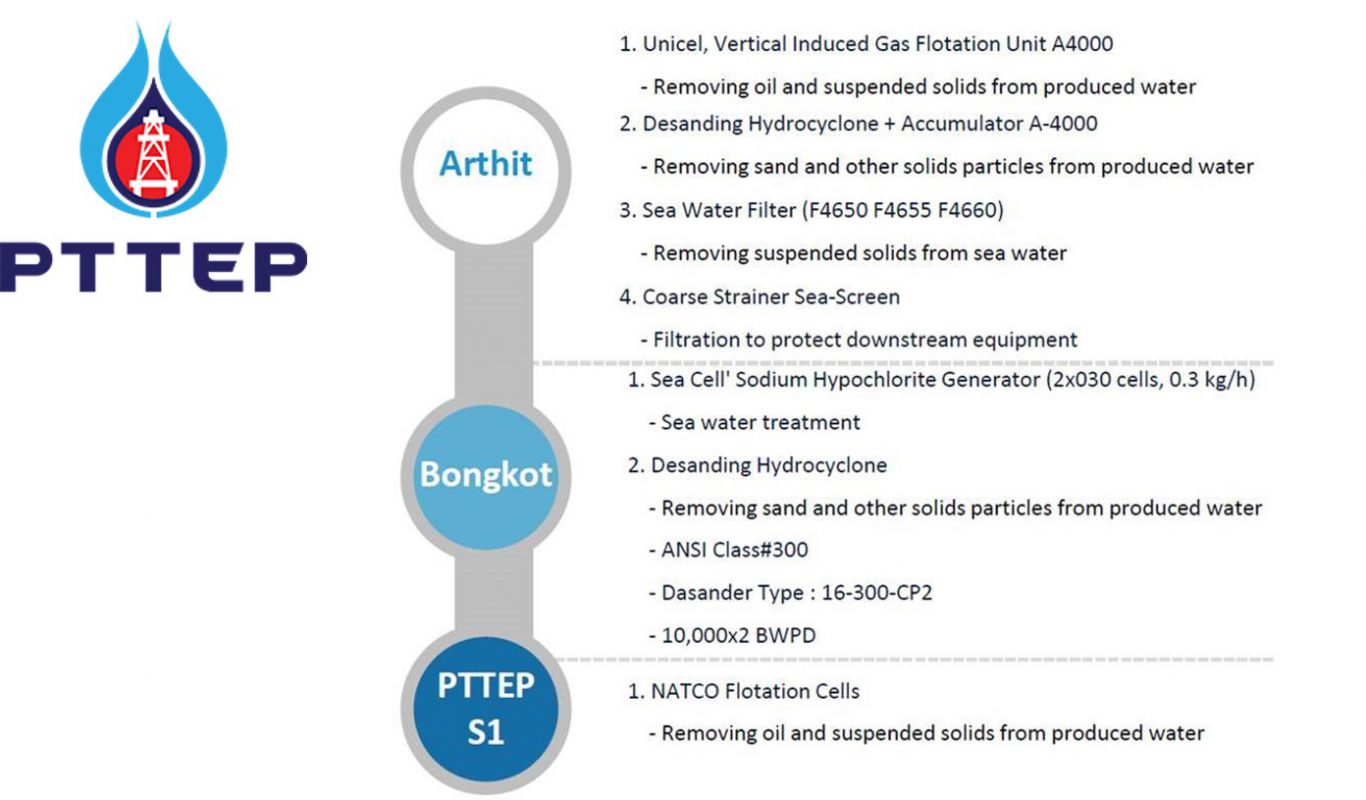

Water is used extensively by the oil and gas industry for cooling, injection, and utility purposes. Sea water requires specific filtration to protect downstream equipment and subsurface formations from contamination and operationally detrimental reactions. Developed and refined through long-term field experience, the METROL SEA-SCREEN coarse strainer provides industry-leading seawater filtration performance and operational reliability.

-

Advantages

- Design flexibility for high flow rates where size and cost are significant factors

- More effective screen backwashing from higher backwash velocities

- Improved reliability and lower operating costs compared with other designs

- Backwash automation removes operator intervention and lowers operating costs

-

Effective 25 um filtration using spiral-wound wedge wire screens

Water enters the METROL SEA-SCREEN coarse strainer into the bottom of the strainer basket, passes vertically upward, and then proceeds radially outward through the strainer screen. The precise, laser-manufactured slots in the spiral-wound wedge wire screen are capable of removing particles down to 25 um. As seawater passes through the screen, solids greater than the size of the strainer slot are trapped on the inner face of the screen. The strained water exits through the vessel outlet.

Application of SEA-SCREEN Coarse Strainer

Water enters the strainer basket at the bottom and passes up and radially outward through the cylindrical strainer basket. Entrained solids larger than the straining slot become trapped in the horizontal recesses on the inlet face of the basket. As the volume of solids increases, the differential pressure across the strainer basket rises, requiring removal of the solids. This is achieved by a high-efficiency automatic backflushing mechanism, which can be initiated in one of three ways

- backflush interval timer

- manual push button

- differential pressure switch.

The SEA-SCREEN coarse strainer stays online during the backflushing process, at almost full forward flow, with no deterioration in strainer performance. There is automatic sequential cleaning in all the strainer baskets within the package. On conclusion of a backflushing sequence, the control system resets automatically.

Project Reference

Brochure

Download