A gasket is an elastomeric component that covers the point where two surfaces meet. They are often made of a range of materials, such as rubber, cork or paper, metal, copper, and foam. Because of its versatility, this adaptable element may be utilized for a variety of applications. These include anti-vibration, packaging, cleanliness, noise and sound reduction, and, perhaps most significantly, sealing. Gaskets are utilized in almost every industry, including food processing, petrochemicals, pharmaceuticals, water, and gas. Gasket materials are selected for their properties and capacity to endure a variety of conditions, including mining and deep-sea environments, as well as resistance to chemicals, alkaline acids, high temperatures, and pressure.

How does a Gasket work?

A gasket must be squeezed enough to create a complete barrier that will form a pressure-tight seal and protect the contents within the seal in order for it to operate properly and seal away any leaks. Furthermore, gaskets protect moving components of an application by preventing them from rubbing against hard surfaces and causing friction. An elastomeric gasket is a component that creates a seal between two surfaces by sealing against the release or intake of both gases and liquids. They are excellent for filling defects and connecting two surfaces. Because a gasket will cover the gap between these two surfaces, it must be made of a material that is readily deformed and fills any imperfections. Compounds such as spiral wrapped gaskets are often made from a combination of metallic and softer filler material (flexible graphite). Metal gaskets must most of the time be squeezed at a greater tension in order to seal accurately. In certain instances, a sealant must be placed directly to the gasket to provide a leak-free seal.

Applications for Gaskets

A gasket is an important component in various production processes since they are available in a variety of specifications. Gasket material is selected for an installation based on properties like as resistance to chemicals, temperatures (or temperature variations), pressures, acids, gases, and, in certain cases, electromagnetic or electrical forces. Gaskets are widely used and may be found in automobiles, trains, aircraft, boats, electrical equipment, pumps, and a variety of other uses.

Industries that make use of gasket

A gasket material has the ability to withstand some of the most demanding conditions for industrial sealing goods, such as:

- Chemical synthesis

- Production of electricity

- Petrochemical and deep-sea exploration

- Oil and gas

- Mining

- Military

- Aerospace

- Filtration

- Food and Beverage

- Pharmaceutical

- Industries involved in sanitary processing

Gaskets may be manufactured using a variety of methods, depending on the material and application, including:

- Extrusion of rubber

- Cold bond splicing and hot vulcanized splicing

- Compression molding, injection molding, and transfer molding

- Slitting with precision

- Personalized die cutting

- Waterjet chopp

Gaskets and seals are used in almost every application and sector, including oil and gas, manufacturing and industrial uses, pulp and paper production, and agricultural equipment. Gaskets that have become worn or damaged are simple to repair. It is common practice to replace gaskets whenever the equipment is dismantled and rebuilt.

PRODUCT OF SMITH Gaskets

RING TYPE JOINTS

Ring joint gaskets are metallic sealing rings suitable for high pressure and high temperature applications and are fitted in ring groove type flanges.They are widely used in the Oil/Gas and Petrochemical industry, in valves and pipe-work. Choice of material may be determined to suit higher temperatures and aggressive media. They comply with ASME B16.20 standards and API spec 6A (where applicable).

The gasket hardness is carefully controlled and shall always be softer than the mating flanges to ensure a good seal and no damage to the flange surface (note: RTJ gaskets should not be re-used). All SMITH RTJ gaskets are manufactured from fully traceable materials and are stamped to the requirements of API 6A and ASME B16.20. DIN 50049 3.1 certification is supplied with all orders. The gaskets are machined to the required tolerances and surface finish using high quality CNC lathes. All soft iron and carbon steel RTJ gaskets are electroplated with zinc 0.0005″ thick in accordance with API specifications. Other non-standard styles of metal rings are also available like combination, IX, Delta and Lens to customer specifications.

1) TYPE R

R type ring joint gaskets are available in oval or octagonal cross section and manufactured in accordance to API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges. The oval ring fits the round and flat bottom ring groove flange, while the octagonal shape fits only the modern flat bottom groove flange.

2) TYPE RX

The RX type RTJ gasket is manufactured in accordance to API 6A and ASME B16.20 to suit API 6B and ASME/ANSI B16.5 flanges. The RX is a pressure energized version of the R octagonal gasket and fits the R type flat bottomed groove.

The RX has an increased height and utilizes the internal system pressure to energize and improve the seal as internal pressure increases. Some RX sizes have a pressure relief hole to equalize pressure both sides of the sealing faces.

3) TYPE BX

3) TYPE BX

The BX type RTJ gaskets are manufactured in accordance with API 6A and are suitable for use in high pressure API 6BX flanges.The gaskets form a metal-to-metal seal on assembly and the efficiency improves as internal pressure increases. All BX sizes have a pressure relief hole to equalize pressure across sealing faces.

- SRX and SBX RTJ gaskets to API 17D for subsea applications.

- IX rings for compact flanges

- Other non-standard styles of metal rings are also available like combination, IX, Delta and Lens to customer specifications

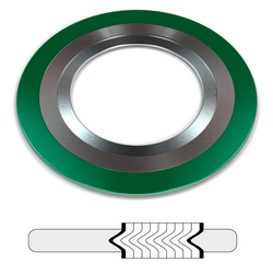

SPIRAL WOUND GASKETS

SPIRAL WOUND GASKETS

Spiral Wound Gaskets are suitable for a wide range of operating conditions and can be adapted to suit almost all applications. The gaskets can seal fluid pressures up to 250 bar and temperature range of -200°C to in excess of 450°C.

THICKNESS : All RS and RSI gaskets for standard flanges have a 4.5mm thick sealing section of windings and filler material, with 3.2mm thick solid metal guide rings.

1) TYPE RS

1) TYPE RS

The standard gasket choice for RF and FF flanges, with the guide ring and sealing element made to ASME B16.20/DIN standards.

2) TYPE RSI

2) TYPE RSI

The standard RS style with an extra inner ring fitted, providing an additional compression stop that protects the sealing element from heat and corrosion.Inner rings are standard on all gaskets NPS24″ class 900#, NPS12″ and above in 1500#, and NPS4″ and above in 2500#. All spiral wound gaskets with PTFE filler material have inner rings fitted.

3) TYPE S

3) TYPE S

Style S gaskets are a sealing element only with a few additional layers of winding strip for use in tongue and groove and male/ female flanges.These gaskets are also available in oval, obround and diamond shape for valve bonnet and handhole applications.

CUT AND SHEET GASKET

CUT AND SHEET GASKET

Non-metallic, flat cut gaskets are used by many industries as they can be made to suit a large variety of applications.

As well as providing products cut to recognized industry standards, SMITH Gaskets also provides a custom service for design and manufacture to fit specific applications. Many factors are taken into consideration when helping you select the right product including temperature, application, media and pressure. SMITH Gaskets stock carries a wide range of competitively priced, utility grade gaskets plus gasket styles to meet varying specific applications such as high temperature, low load, high torque and high pressure for many different media. A comprehensive range of rubber, non-asbestos, virgin and modified PTFE, and graphite grades (industrial and high purity) in sheet, roll and cut gasket forms are available in stock.

1) NON-ASBESTOS GASKETS

- SMITH U-MAX

Utility grade gasket material. Organic fibres, NBR

Application: Good resistance to water, gases, oils, gasoline/fuels, mild acids and alkalis.

180 oC / 356 F; 40 bar / 356 psi

- SMITH UW-MAX

High strength / pressure wire re-inforced. Synthetic fibres, NBR/SBR, Wire re-inforced

Application: Water, gases, gasoline/fuels, excellent dynamic and thermal resistance.

400 C / 752 F; 140 bar/2030 psi

- SMITH Y-MAX

General purpose gasket material. Aramid fibres, NBR.

Application: Good resistance to water, gases, oils & fuels. Approved for BAM (Oxygen);

BS7531 grade Y and WRAS (potable water) and TA-Luft (VDI 2440)

350 C / 662 F; 100 bar/1450 psi

- SMITH CF-MAX

Carbon Fibre, NBR. High pressure / High temperature, ideal chemical and petrochemical industry material.

Application:Saturated steam, aliphatic (light) hydrocarbons, hot oils, gasoline,chemicals & refrigerants.

Approved for BAM (Oxygen) and BS7531 grade X.

400 oC / 752 F; 100 bar/1450 psi

- SMITH X-MAX

Glass Fibres, NBR. Excellent torque retention, good steam and thermal resistance.

Application:Water, Oils, gases, fuels, organic and inorganic acids. Approved for BS 7531 grade X and TA-Luft (VDI 2440)

- PTFE SHEET

Application: Acid and chemical resistant. 260 oC / 50 bar.

2) ELASTOMERS

- Neoprene (CR )

Applications: Good oil and petroleum resistance.

940oC / 17 bar.

- Nitrile (NBR; Buna-n)

Application: Good resistance to oil, solvents and fuels.

94oC / 17 bar.

- Ethylene propylene Diene Monomer (EPDM)

Application: Good resistance to ozone, sunlight, acids, alkalis and ketones.

Not suitable for fuels and oils. 120oC / 17 bar.

- Fluoroelastomer (FKM) Viton®

Application: Excellent resistance to heat and oil combinations and a wide range

of concentrated acids and chemicals.

205o C / 17 bar.

- Styrene butadiene (SBR; Buna-S)

Application: Good abrasion and impact resistance – general purpose sheet.

Not suitable for oils, fuels and solvents.

94o C / 10 bar.

3) FLEXIBLE GRAPHITE SHEET PRODUCTS

- SMITH GRAFMAX

Pure flexible graphite without steel insertion.

Application: Steam, hydrocarbons, most chemicals.

Not suitable in strong oxidizing media. 450oC / 80 bar.

- SMITH GRAFMAX F

Pure flexible graphite with 0.05mm flat AISI 316 foil insertion.

Application: Steam, hydrocarbons, most chemicals.

Not suitable in strong, close-up oxidizing media. 450oC / 100 bar.

- SMITH GRAFMAX T

Pure flexible graphite with 0.1 mm AISI 316 mechanically bonded tanged insertion.

Application: Steam, hydrocarbons, most chemicals.

Not suitable in strong, close-up oxidizing media. 450oC / 200 bar.

- SMITH GRAFMAX PREMIUM

A range of high purity (99%), high temperature and oxidation resistant graphite sheets and strip for critical service applications.