Although the electricity is in limited situation, absorption chiller also can activate. Furthermore, it only consumes a small amount of electric energy in the systems, compared to electric chillers.

During the process, the absorption chiller uses a lithium bromide solution (LiBr) as the absorbent and water as the refrigerant. The reason a lithium bromide because of not being a hazardous chemical. Another outstanding characteristic is non-CFCs and non-HFCs which are harmful to the environment.

Here are more advantages of Absorption chiller: Driving power from Heat Energy, Less electric energy consumption, Easy maintenance, Low maintenance costs, Less noise and vibration, Non-CFCs or Non-HFCs refrigerant and Environmental-friendly.

Principle

Firstly, weak solution in the absorber which is suitable for concentration mixed with lithium bromide solution and water is pumped through the heat exchanger. Then, It becomes the intermediate solution before flowing into the generator separating the water and lithium bromide solution. The generator utilizes the heat energy from waste heat such as Flue gas, Steam or Hot water.

In the Generator, the water will be changed to vapor and leave the lithium bromide solution, but it will not be left as a waste. It will be formed as a liquid and drop to bottom of the generator. The liquid flows down to preheat the weak solution in the heat exchanger and becomes strong solution. Then, it flows back to spray over the absorber to absorb the vapor for next process again.

Meanwhile, the vapor which left from lithium bromide solution in generator flows into the condenser. The solution will be cooldown by the cooling water, then it will be condensate to the refrigerant. It flows down to the evaporator due to the vacuum condition which made the water boiling temperature becomes low.

In the Evaporator, 12°C chilled water which returns from operation system flows into the evaporator. The unwanted thermal energy will be extracted by spraying refrigerant over the chilled water pipe in the evaporator. Therefore, the chilled water temperature will be decreased to 7°C.

Finally, after the refrigerant water extracted unwanted thermal from chilled water, it will become the vapor again as low boiling temperature under the vacuum condition in the evaporator. After that, the vapor will be absorbed by strong solution and become weak solution for the new cycle again.

Shuangliang Waste Heat Recovery Solution Provider

Shuangliang has dedicated to the study of industrial waste heat recovery over 3 decades. As endless attempt, Shuangliang is gradually developing from as equipment supplier into a system provider.

About 60% of all energy generated in the world is left as a waste heat. Unfortunately, most of the waste heat will be degraded as traditional heat recovery technologies can’t activate effectively. From this point, Shuangliang Eco-Energy System Co., Ltd. wants to solve this problem by turning it to useable energy.

Shuangliang Eco-Energy Systems Co., Ltd. has been founded since 1982. According to the expertise, it is the first and only listed company in the absorption chiller industry. Eventually, the company joined with Shuangliang Group, a large enterprise that provides manufacturing, chemical and materials, and hotel services.

Product

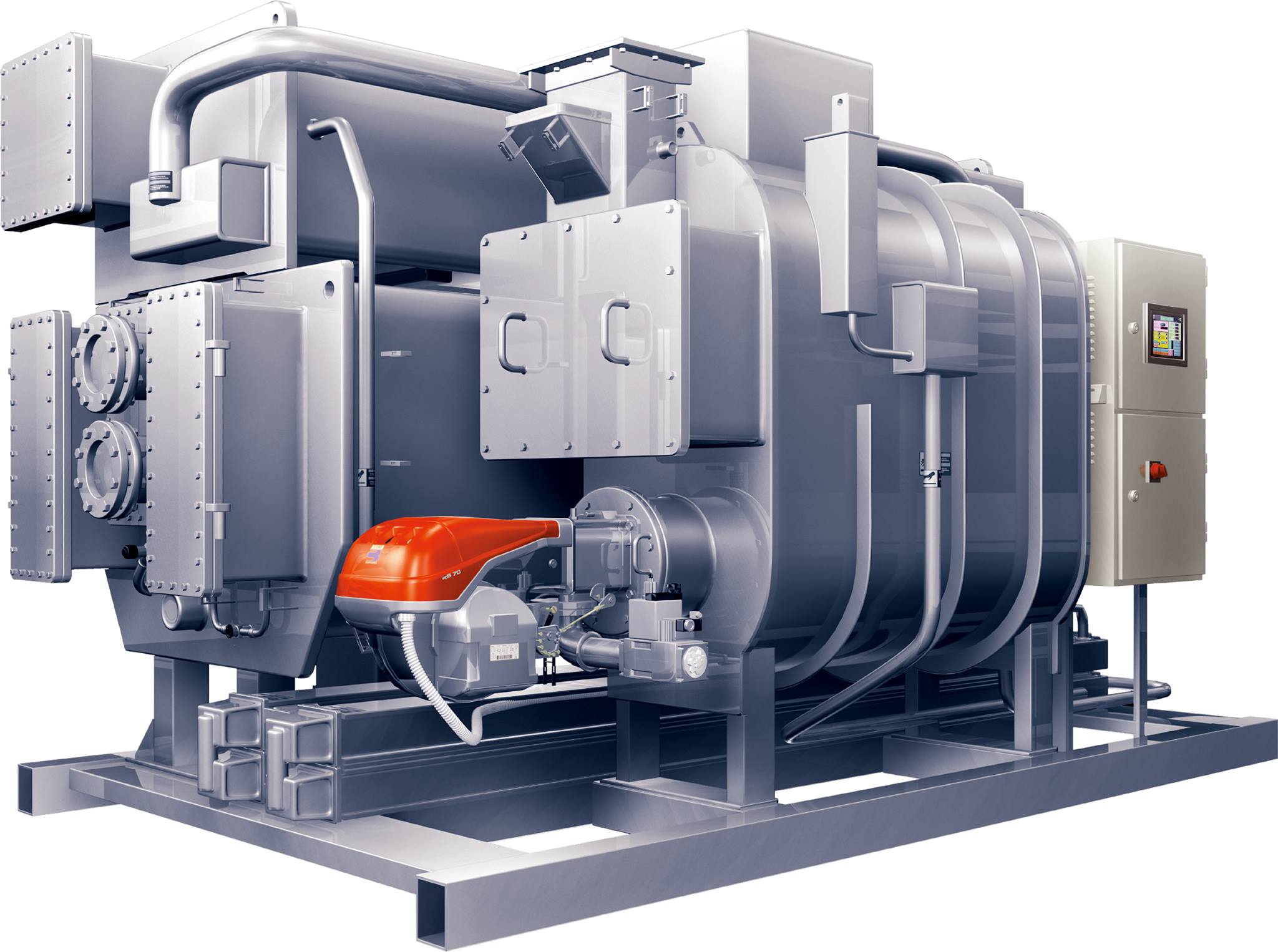

- Flue Gas Lithium Bromide Absorption Chiller

Flue gas absorption chiller is applied as an important role of the tri-generation system. Normally, gas engine produces electricity while exhaust heat drives an energy of absorption chiller. According to this process, the waste heat from gas engine can provide cooling capacity for any communities and buildings.

As a combination of cooling, heating, and power generation system, the flue gas absorption chiller can increase capacity utilization and efficiency up to 85%. Moreover, the absorption chiller enhances power supply safety from the grid and leads more electricity saving. From several advantages, the absorption chiller can enhance environmental protection and sustainably economic development.

-

Direct Fired Lithium Bromide Absorption Chiller

Due to the increase of electricity price and continual concern to environmental issues, Shuangliang eco-energy develops the high energy-efficiency. Absorption chiller is energized by the heat from directly burning light oil, heavy oil, industrial gas, or natural gas. By using heat of different levels, the direct fired absorption chiller can produce chilled water temperature from 5 °C to 7 °C which mostly used in the air conditioning system.

-

Steam Lithium Bromide Absorption Chiller

The Steam Lithium Bromide Absorption chiller is one of Shuangliang famous models. Steam pressure with 0.01-0.15 MPa can provide a cooling capacity of 350~11630 kW. Also, 5°C to 7°C chilled water is suitable for the central air conditioning system or industrial process.

Due to its advantage, waste steam from the steam turbine in power generation can be reused as an energy for absorption chiller, also steam from the boiler

Especially, Shuangliang double-effect absorption chiller is in the most leading manufacturer. With high COPs of 1.43, it can provide high efficiency, low energy consumption and low-operating costs.

-

Hot Water Lithium Bromide Absorption Chiller

With Shuangliang standard specifications, the temperature range of hot water about 90°-130°C is applied as a main role of the hot water single stage and two-stage absorption chillers. Moreover, Shuangliang standard specifications are available for suitable temperature and customer’s requirement.

The cooling capacity of hot water absorption chiller is between 350~6890 kW. As the chilled water temperature is about 5 °C – 7 °C which is useful for air conditioning system and industrial process.

To reuse waste heat recovery, utilizing waste hot water from gas engine or other industrial process in hot water absorption chiller is one of effective ways to save energy, reduce electricity cost and saves considerable amount of operating costs.

Benefit / Shuangliang Absorption Chiller

Technical Advantages

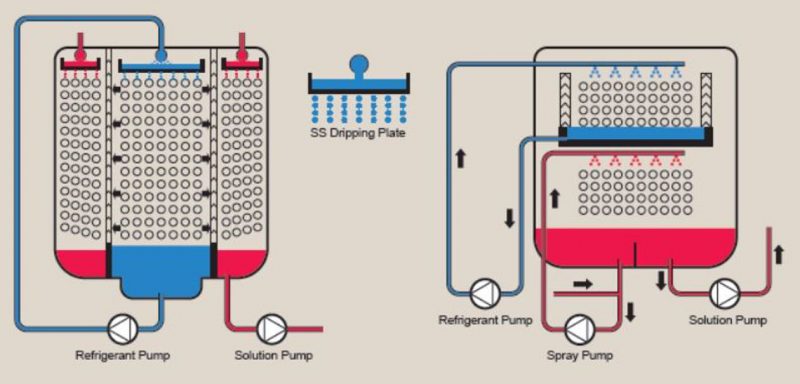

1.Two Pumps and without Spray Nozzles

Outstanding design is dripping plates instead of spray nozzles. Plus, it has Left-Middle-Right arrangement: absorber-evaporator-absorber. This configuration will help avoid the decrease of cooling capacity and prolong the operation of chiller. Furthermore, the absorption chiller does not need to use spray pump, since the solution goes down with gravity flow in absorber part.

2. State-of-the-Art Liquid Heat Exchanger

High-efficiency heat transfer tubes with new flow pattern can also reduce flow pressure drop.

3. Distribution of Refrigerant by Dripping Plates in the Evaporator

SS Dripping plate is the most famous function because of reducing liquid film thickness,improving operating efficiency and using without spray nozzle pump.

4. High Quality Tubes and Optimized Flow Arrangement in Evaporator

High quality tubes ensure the distribution of heat transfer effect in the evaporator which enhances heat transfer efficiency.

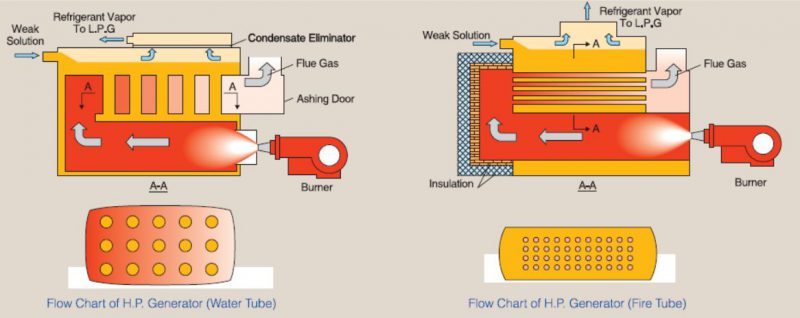

5.Special Construction of High-Pressure Generator for Direct-Fired Chiller

This exclusive construction, which is inside solution tubes and wet back of combustion chamber, improves operation safety and reduces fuel consumption.

6.Heat Transferring Technology

Our advanced technology of heat transferring ensures safer operation and extends life cycle. Apart from that, this also enhances higher heat transfer efficiency.

7. Anti-Freezing Technology

Evaporator tubes are protected from freezing. It is realized by collecting the refrigerant water from the condenser at the bottom chamber of the evaporator, and then pumped to the dripping plates. In addition, the refrigerant dripping process would stop immediately if the refrigerant pump was powered off.

8. Serial Flow of Solution

Series Flow Solution patterns improves reliability and simplify the control of crystallization.

9. Non-condensable Gas Purging System

Air inlets of purging device arranged inside the unit to ensure optimum air suction performance.

10.Non-condensable Gas Auto Discharge System

Non-condensable Gas Auto Discharge System controls the start-up and shutdown of the Solenoid valve . In addition, the systems activates by the High-Low pressure settings of auto-purging cylinder.

11. SL Remote

SL Remote monitoring system is a Shuangliang internal servers. It is used for monitoring and functioning for data collection, online monitoring, data storage and management, data analysis and expert diagnosis, fault early warning and alarm which users can easily visit through website.

Commercial Advantages

-

Lowest Social Cost

In contrast with an electric chiller, Shuangliang absorption chiller uses driven heat sources because it , helps save number of investments in the construction of power station and other electricity infrastructure.Shuangliang absorption chiller product is one of your best choices for sure.

-

Competitive Price

Due to practical design, it reduces costs on production and shipping expenses. Also, our advanced concept can lower manufacturing cost, be assured of its capability and optimize customization.

-

Quick Time-to-Market

As our great proficiency, your desired absorption chiller can be possible in short time.

4.Lowest Possible Operating Cost

Beacuase of the relative compact and lightweight design, Absorption chiller has a smaller footprint and reduced foundation dimension. Energy-saving features also help save operating costs. Highly reliable design and manufacturing technologies enable rugged absorption chiller whcih requires less maintenance

Above all, all these advantages guarantee customer’s satisfaction for a long time.

Solution & Service

Sale-Service

- Design

Professionals at our postdoctoral station, state-level enterprise technology center ensures an accurate design of your desired equipment.

- Production

Shuangliang has the largest production line in the world absorption chiller industry with Demand Flow Manufacturing technique (DFM) in production process. With advanced techniques and equipment, our customers can ensure the maximum reliability of finished products

- Quality Guarantee

Before installing in customer’s site, each product needs to be checked by helium leak detectors at a leakage rate of 1×10-10 Pa·m3/s.Normally, it’s 4 times lower than than Japanese Industrial and Chinese National Standard by specified rate of 2.03 ×10-6 Pa·m3/s.This process guarantees the quality of finished products.

- Performance Test

When you choose from SHUANGLIANG products , you can assure of high quality with an absorption unit that provides decades of care-free performance.

- Project Design

Since customer is our priority, Shuangliang experienced team promises to design the best solution for your project.

- Onsite Installation

To make sure of your onsite installation, our experienced engineers will look after this process. Therefore, your project will be finished on time and with high quality.

- Commissioning

After installation, our engineers would commission the units while maintaining 24-hour remote control over the whole system. This process ensures the product quality and service life.

After-Sales Service

- Training Program

The operators training program will be held on a regular basis .The program provides our sales agents and equipment users with professional theoretical knowledge.

- Service after Purchase

Shuangliang ’s professional service team makes sure that each of our 20,000 equipment sets we sold can be delivered in time, effective, and corrective maintenance service.

Shuangliang Reference

Shanghai Disneyland in China

Shanghai Disneyland, distributed energy has the advantages of saving transmission and distribution investment, improving energy utilization efficiency, achieving dual “peak cutting and valley filling” of natural gas and electricity, flexible start and stop of equipment, and improving system power supply reliability, safety, energy saving and environmental protection.

Chiller Type: Shuangliang Multi-Energy absorption chiller 5 units utilizing with Jenbacher JMS 624 gas engine 5 units.

Absorption chiller cooling capacity: 19,655 kW

Comprehensive energy utilization efficiency: 85.9% and the modern energy supply mode of energy supply near the load center is a highly important natural gas high efficiency utilization mold.

Total cooling capacity: 5500 USRT

Shijiazhuang People’s Hospital

Chiller Type: Shuangliang Flue Gas and Hot Water operated absorption chiller

Total Cooling Capacity: 1,680 USRT x 2 units

The main equipment includes:

- Combustion Gas Engine 2 Megawatt x 2 units

- Flue Gas & Hot water LiBr Absorption Chiller x 2 units

- Centrifugal Chiller x 3 units

- Hot water / Gas-fired Boiler x 3 units

- Heat Exchanger x 3 units

Economic and Environmental benefits:

- Increasing use rate of cooling, heating and power generation 86.6%

- Compared with conventional coal-fired thermal power plants.

- Saves 2974.35 t/a of standard coal per year with an energy-saving rate of 27%

- CO₂ emission reduction 12156.18 t/a with a reduction rate of 48%

Pfizer Asia Pacific Pte. Ltd., Singapore

Chiller Type: Shuangliang Steam operated absorption chiller

Total cooling capacity: 2000 USRT

Power Generation: Solar gas turbine and Heat Recovery Steam Generator

Chiller: 3 sets Shuangliang steam chiller

- Absorption chiller cooling capacity: 3 x 2330 kW

- Pfizer Asia Pacific Pte. Ltd. is a base of Pfizer Inc., which is the world’s largest research-based pharmaceutical company.

- Located within Tuas Biomedical Park, Pfizer’s Active Pharmaceutical Ingredients (API) manufacturing plant started operations in 2003.

- The site covers about 22 acres and employs close to 400 colleagues.

Beijing Conference Center for 2008 Olympic Games

Chiller Type: Shuangliang Flue Gas operated absorption chiller

Total Cooling Capacity: 1,122 USRT x 2 units

Genset: 2 units of GE JENBACHER JMS312 GS Gas engines

Chiller: 2 units of Flue Gas Operated Lithium Bromide Absorption Chiller

Output Power Capacity: 2 × 512 kW

Output Cooling Capacity: 2 × 3940 kW = 7,880 kW

Output Heating Capacity: 7,103 kW

Energy Saving & Environmental Protection:

- The units save 5,633 tons of steam every year, cut power consumption at a rate of 3 MW/hour and reduce 17,000 tons of CO2 emissions.

- SHUANGLIANG waste heat utilizing solution helps improve fuel efficiency of the genset up to 85%.

Beijing Capital International Airport

Chiller Type: Shuangliang Direct Fired operated absorption chiller

Total Cooling Capacity: 6,012 USRT

Energy Saving Performance:

- Our chiller helps save 8MW of electricity per hour, which translates into a coal saving of 20,000 tons and a reduction in carbon dioxide emission of 52,000 tons.

- As a famous landmark once built-in preparation for the 2008 Olympic Games, Beijing Capital International Airport as contracted part of its central conditioning system project to our company.

- This is the second time that we have become the partner for the Olympic Games.

Beijing South Railway Station

Chiller Type: Shuangliang Flue Gas operated absorption chiller

Total Cooling Capacity: 992 USRT

- With a total cooling capacity of 992RT, our flue gas operated absorption chiller proved to be a nice fit for the cogeneration system installed inside the Beijing South Railway Station, every time the chiller operating can be saving money.

Energy Saving Performance:

- It is estimated that the chiller helps save 5,633 tons of steam, 28.2 million kW of electricity, and reduce 8,000 tons of carbon dioxide emissions produced from burning coals.

- Reportedly the largest in Asia, Beijing South Railway Station serves as the terminus for high-speed trains to the city, including the Beijing–Tianjin Intercity Rail which can reach speeds above 350km/h.

- The structure spreads out like a ray or trilobite and covers 320,000 m2, 24 platforms have the capacity to dispatch 30,000 passengers per hour or 241,920,000 a year. The 251,000 m2 waiting area can accommodate 10,000 passengers.

Honorary qualification

Won two “Industrial Oscars” for Chinese Industry

The State Council approved the establishment of China’s highest award in the field of industry, energy conservation and environmental protection in the field of the only honor.The China Industry Awards are the highest award in China’s industry, the most influential award, and the most rigorous award. The first was awarded in 2016 and the second was awarded in December 2020 for the Intelligent All-Steel Structure Natural Ventilation Cycle Water Cooling Project.

- Won the Ministry of Industry and Information Technology air-cooled island single champion

- Selected for “Great Power Heavy”

- China’s industrial demonstration enterprises

- China’s industrial pioneer demonstration unit

- China’s first service-oriented manufacturing demonstration enterprises

- National machinery industry advanced collective

- Won the Ministry of Industry and Information Technology lithium bromide single champion

- National machinery industry civilized units

- National after-sales service meritorious enterprises

- National after-sales service industry top ten units

- Five-star service top 100

- Equip China’s meritorious enterprises

Shuangliang award

Shuangliang Eco-Energy has received Special award-winning of the China Distributed Energy Excellent for 7 Years consecutively

- 2020 Shijiazhuang People’s Hospital

- 2019 Xiangjiang Happy City

- 2018 Zhuhai Hengqin Intelligent Energy

- 2017 Wuhan International Expo Center

- 2016 China National Convention and Exhibition Center

- 2015 Shanghai Disney Resort

- 2014 China Petroleum Technology Energy Center

Shuangliang Eco-Energy will continue to be driven by technological innovation. Also, it focus on energy conservation and environmental protection industries, and provide advanced support for green development.