Shuangliang Solar-Tech (Baotou) Co., Ltd.

Business Coverage

Energy & Environment Conservation

- Energy & Water Saving

- Environment Conservation

- Smart Energy

Lithium Bromide absorption chiller, heat exchanger, air-cooled condenser, Energy & Aqua management

Clean Energy

- PV Energy

- Polysilicon reduction furnace

Silicon wafer, PV module, Distributed PV power

New Chemical Materials

- EPS

- Spandex

- BOPP films

Bio Technology

- Bio medicine

- Organic fertilizer

Shuangliang Solar-Tech Globalization

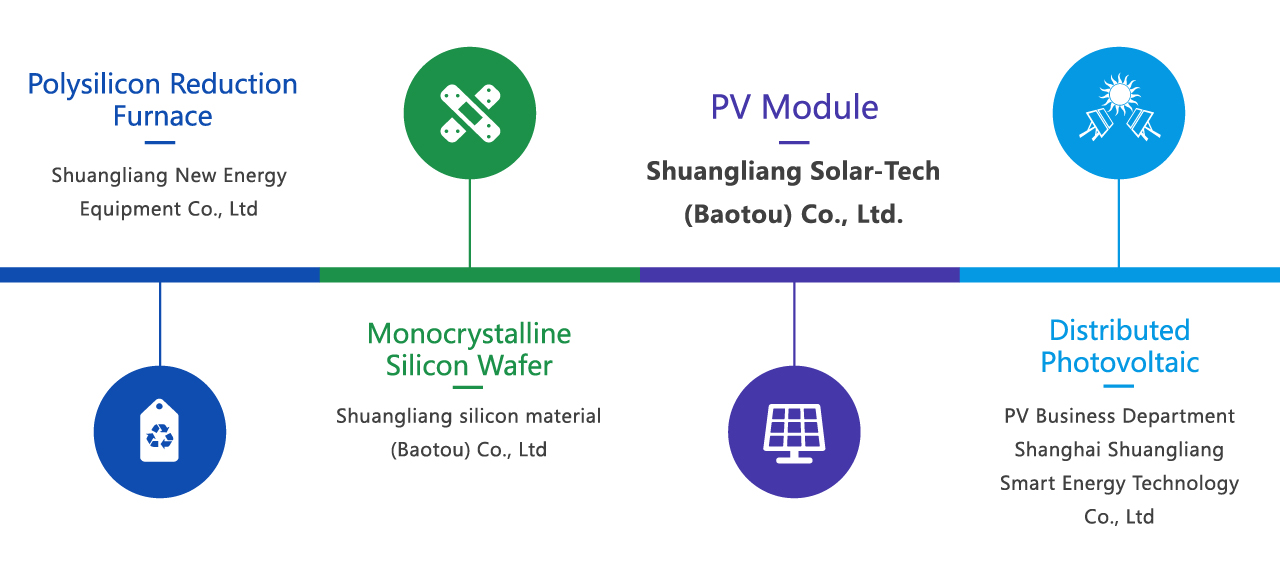

Shuangliang PV Industry Chain

Silicon Material

Production Capacity 40 GW

- nCompatible with 182-230 sizes

- nFlaked, P/N types compatible

- nMaximum charge of single furnace 4000kg

PV Modules

Top 10 In Scale

Top 10 component manufacturing capacity.

5GW in phase I. 20GW in total.

- 182 modules

- 210 modules

- Compatible SMBB

- PERC

- TOPCon

- Heterojunction battery module production

Advance Equipments

Leading the development of next-generation module technology, and the size of compatible battery chips is developing from 182 to 210

Development of 50/55/60/72/78 chip version from single glass to compatible dual glass / transparent backplane components

Shuangliang Supply Chain Management

Shuangliang adheres to the concept of open innovation and coordinated development, and combines the strength of industrial chain partners to open up the links of R & D, manufacturing and application, so as to accelerate the industrialization and harmonious development of high-efficiency photovoltaic modules.

Shuangliang Product Portfolio

Higher Customer Value

- Lower system investment costs;

- The maximum power can reach 660W;

- PV panel conversion efficiency 21.3%-22%;

- Lower decay values;

- Excellent bifacial rate, high compatibility to the tracking system of the power station due to the framed design and it can increase output power effectively;

- Positive Power Tolerance

Higher Reliability

- Non-destructive cutting method is adopted to reduce the risk of cracking;

- Strictly control the product quality from the silicon material;

- 12-year material process warranty, 30-year linear perfomance warranty;

- Guaranteed by anti-PID test under strict conditions;

- String welding equipment is equipped with EL string inspection (with AI recognition);

- Three EL inspections of components (with AI recognition) carried out before/after the lamination of the whole line and the final inspection implements