Heat Exchanger for Geothermal Power Plant

Function

Based on organic Rankie’s circulation (ORC) principle, use the industrial low temperature waste heat or geothermal for driving heat source, to produce high quality electric power.

ORC power systems are composed of expander, pre-heater, condenser, regenerator, evaporator, etc. which Shuangliang supplied all of them.

Main Clients

- Atlas Copco

- SIS Enerji Uretim A.S. (Turkey)

- LIANYOU Mechnical

- Exergy (Italy)

- Egism (Turkey)

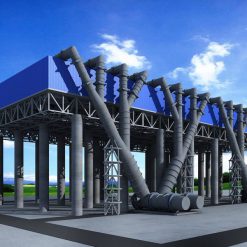

Air Pre-treatment System for PTA Plant

Application

Cooling and Dehumidifying summer air to increase compressor’s efficiency.

As humidity of summer air is high, efficiency will be lower if air comes into compressor directly from filter.

If adding one cooling and condensing system between filter and compressor, most of moisture in air will be removed, which will make compressor operating efficiently.

This is one energy-saving and production increasing process for plant.

Main Clients

- BP

- Man Turbo

- Linde Engineering

- Xianglu Petrochemical

- Zhejiang Yisheng Petrochemical Co.,Ltd.

- Jiaxing Petrochemical

- Oriental Petrochemical Corporation

- Dalian Hengli Petrochemical

Safety Heat Exchanger

Application

Heat combined feed heat exchanger is one of the critical equipment in the propane dehydrogenation (PDH) unit, which is listed as the highest safety requirement level IV in the technical specification.

Core Technologies

- Ultra-long tube bundle assembly technology

- Butt deep hole welding technology

- Strict requirements for Helium gas leak detection

Main Clients

- Jiangsu Leasty Chemical Co.,Ltd

- Zhejiang Satellite Energy Co.,Ltd

- Heilongjiang Anruijia Petrochemical Co.,Ltd

- Shandong Shounguang Luqing Petrochemical Co,Ltd

- Hebei Xinxinyuan Energy Co.,Ltd

Double Tube-Sheet Heat Exchanger

The tube side medium and shell side medium will be mixed due to leakage caused by the long-time service and corrosion etc., which can cause serious consequences, such as medium pollution, reaction and even explosion.

BY adding a tube sheet to each tube sheet on the structural basis of the common fixed tube-sheet heat exchanger can prevent effectively the hidden danger and reach the double-insurance effect.

Shaungliang Group has provided more than 3,000 double-tube sheet heat exchangers for clients.

Main Clients

- Xinjiang DAQO New Energy Co.,Ltd.

- Sinopec

Vaporizer

Application

Heating liquid gas (such as nitrogen, oxygen, liquefied petroleum gas (LPG), liquefied natural gas (LNG), liquefied carbon dioxide, etc.) to make it into a gaseous gas.

Type of vaporizer

Divided into vertical coil and horizontal U-tubes of two types. Liquid gas flow Tube side, hot water flow tube outside.

The core components is bare tube or low finned tube.

Main Clients

- Air Liquide

- Air Products

- Saudi Aramco

- Sinopec

- Xinjiang DAQO New Energy Co.Ltd

- BASF

Vacuum Condensing System / Condenser

Application

To condensate the exhaust steam from steam turbine into water, form and maintain a high vacuum, improving the efficiency of the steam turbine. The power released by the exhaust steam condensation are taken into cooling tower through cooling water.

Condenser

It is used to condensate the exhaust steam from turbine into water, form and maintain a high vacuum,

improving the efficiency of the steam turbine. The power released by the exhaust steam condensations are taken into cooling tower through cooling water.

Condensing System

In addition to the condenser, we can also provide the condensing system including:

- the condenser

- steam jet emanation

- safety valve

- drain water expansion tank

- exhaust steam nozzle (including expansion)

- circulating pumps

- valves

- meters

- connecting line etc.

Main Clients

- XiShan Coal Electricity Group Co.,Ltd.

- Siemens Power Generation

- Air Liquide

- Xi’ an Shaangu Power Co.,Ltd.

- Man Turbo

- China Tianchen Engineering Corporation (TCC)

- Chang Chun Group (Taiwan)

Compressor Inter-Stage Gas Cooler and Regeneration Gas Heater

Application

The cooler mainly used in electricity, air separation, chemical industry, pharmacy, etc. where multistage compressors are widely applied for cooling down air, optimizing efficiency and guaranteeing the pressure.

The cooler has image of the lung of the compressor which directly influence performance and efficiency of the compressor.

Main Clients

- Air Liquide

- Air Products

- Siemens

- Linde

- MAN Turbo

- Atlas Copco

- Kobe Steel

- Mitsubishi Heavy Industry

TEMA Heat Exchanger

Application

It carries on heat exchanger the most common application, especially in industries such as chemical industry, petroleum, petrochemical industry, power generation, light industry, heating, etc.

- Feed Super Heater

- PSA Hydrogen – Cooler

- Gas Cooler

- Air Cooler

- Rebolier

- Evaporator

- Heat Exchanger

- Recycle Gas Condenser

- Flare gas heater

- Process Gas Cooler

Main Clients

- EPC companies in Oil & Gas, Petrochemical, Power Generation, Chemical industries such as:

- Hyundai Engineering

- China Tianchen Engineering Corporation (TCC)

- Hualu Engineering & Technology Co.,Ltd.

- Xinjiang DAQO New Energy Co.,Ltd.

- Dalian Hengli Petrochemical

- Petrochemical Industries Design & Engineering Co.

- Sinopec Engineering Company

- Nanjing Chemical Construction Co.,Ltd.

Pressure Vessel

Shuangliang can also customize various types of pressure vessels according to customer needs, such as towers, reactors, storage tanks, etc.

Main Clients

- Sichuan Yongxiang Polysilicon Co., Ltd.

- Ningxia Sunshine Silicon Industry Co., Ltd

Main Clients

- GCL-Jiangsu Zhongneng Solar Technology Development Co., Ltd.

- China Tianchen Engineering Corporation (TCC)

- GE

Main Clients

- Sichuan RuinengSilicon Materials Co., Ltd.

- GCL -Jiangsu ZhongnengSolar Technology Development Co., Ltd.

- Ningxia Sunshine Silicon Industry Co., Ltd

Project Reference

2006, Shuangliang supplied 64 equipment for 8 sets of 110,000 Nm³/h air separation unit for SHELL which export to Qatar.

2015, Shuangliang supplied 103 heat exchanger equipment for 6 sets of 100,000 Nm³/h air separation unit for AP/Siemens which export to Saudi Arabia.

2015, Shuangliang supplied 7 sets heat exchanger equipment for Atlas Ozmen Geothermal Power Plant Project in Turkey.

2016, Shuangliang supplied 23 sets heat exchanger equipment for AP Baytown Hy co plant Project

2018, Shuangliang supplied 100 sets heat exchanger equipment to Hegli 20 million tons/year refining and petrochemical complex project – including coal to hydrogen 6 x 80,000 Nm³/h (Oxygen) Air Separation Unit, Disambiguation Unit, PSA Unit.