Generally, applying another type in an insufficient-water area needs to make a water reservoir to collect the water for serving cooling tower. Thus, Air cooled condenser (ACC) will help reduce capital cost of such a water reservoir, save water consumption cost during operation. Also, it solves the problem of diverting water from the community.

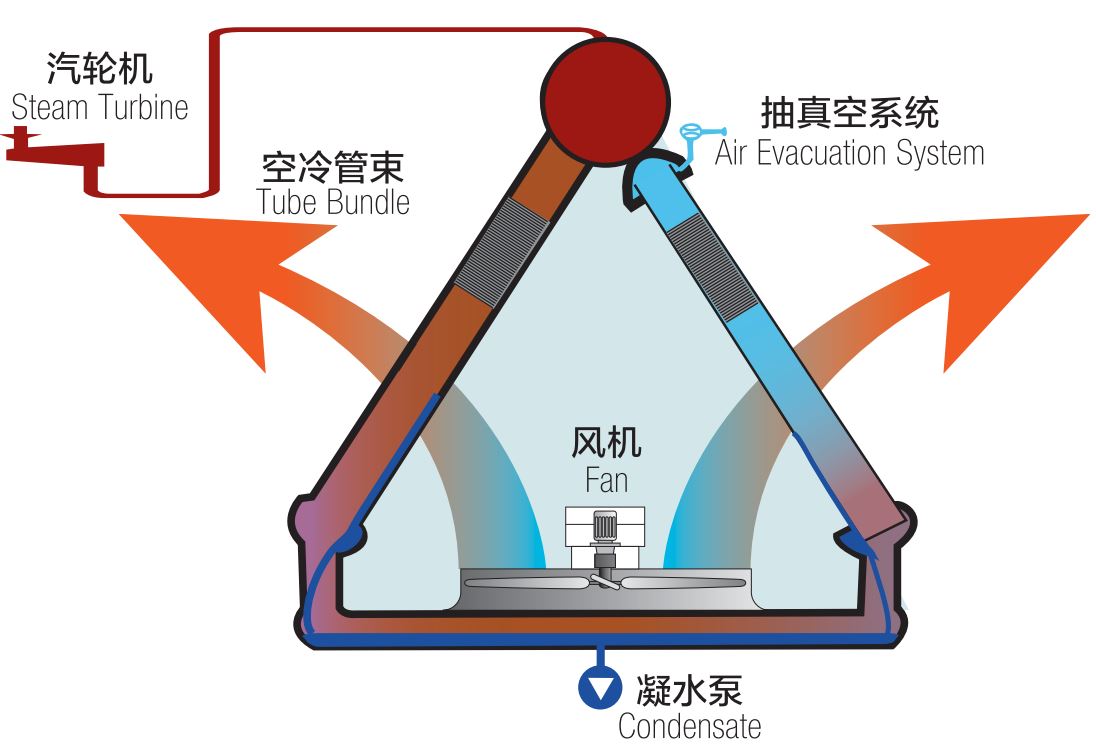

In the thermal power plants, exhaust steam from the steam turbine flow into the air cooled condenser (ACC) where the condensation occurs. Then the condensate-water returns to the boiler in a closed loop. Meanwhile the exhaust steam coming from the turbine is at a low pressure, the Air Cooled Condenser works at pressure as vacuum to avoid the pressure drop increase and impact to the efficiency of power generation, and then the non-condensable gases will be removed continuously by the air evacuation system.

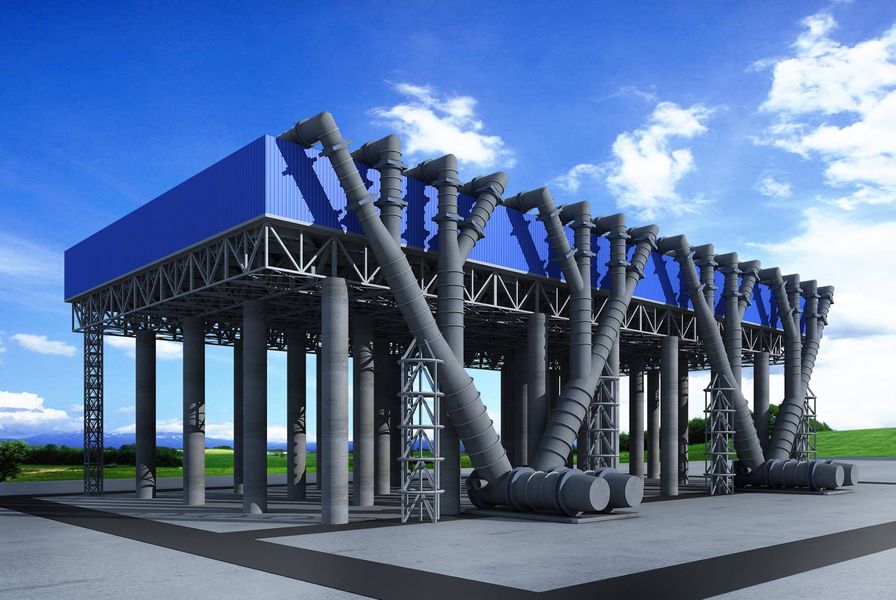

Configuration and Scope of Shuangliang Air Cooled Condenser

Scope normally covers equipment and ducts from turbine exhaust to inlet of condensate pump, mainly including:

- Tube bundle

- Air supply system

- Air evacuation system

- Condensate system

- Cleaning system

- Exhaust steam ducting system

- Supporting structure

- Draining system

- Electric system

- Instrument & control system

Principle of Air cooled condenser

The working principle of Air Cooled Condenser is to distribute the exhaust steam from the steam turbine straightly to the stream condensers in several rows through ducting. At the same time, the large axial-flow fans intake air and sweep over the tube bundles externally to carry away heat. In tube bundles, the exhaust steam gradually changes to condensates and is accumulated in the condensate tank through the bottom headers. Moreover, the vacuum of the whole Air cooled condenser (ACC) covers by the air evacuation system. For this reason, the steam turbine can activate smoothly and confirm power generation efficiency.

The steam condensers are consisted of two types of tube bundles: parallel- flow and counter-flow types.

In the parallel-flow tube bundles, most of the steam is condensed, meanwhile the non-condensing gas is extracted in counter-flow tube bundles which they are connected through the bottom headers.

Additionally, the advantages of the direct air cooled condenser system (ACC) is occupying less floor area, various anti-freezing methods and flexible arrangement.

Technical and Advantage of Shuangliang Air cooled condenser

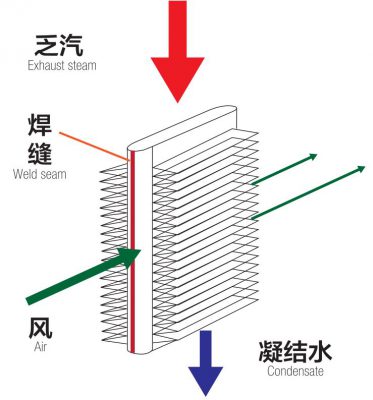

Single-Row Tube

Shuangliang Single-Row Tube is one of the best selective innovations which is applied in Air Cooled Condenser (ACC), characteristics designed by welded large flat tube and aluminum snake-like fins, are rolled from single-sided aluminum cladded carbon steel strip. The flat tubes and fins are connected by brazing.

1. High heat transfer efficiency

The heat exchange at both sides of tube bundle is fully activating, mean to the exhaust steam has large size of flow area and very low-pressure loss, so the heat transfer efficiency is extremely high.

2. Strong resistance to corrosion

To have strong corrosion resistance, the external surface of base tube for the tube bundle is clad with aluminum alloy, the heat exchange fins of tube bundle also aluminum alloy spray coating, even after those materials are processed, aluminum oxide protective layer will still be formed thereon to achieve good corrosion resistance.

3. High strength and good cleaning ability

Welding several single-row fin tubes and tube-sheet was also applied in order to strengthen all the structures. Moreover, this process would apply for facilitate installation and transportation. Another distinctive characteristic, using straight-line type in single-row tube fins are easy to wash with high-pressure water without any deformation.

4. Good anti-freezing performance

In order that the condensate flows more smoothly, we create a large length-width ratio of the base tube. Furthermore, this specific characteristic is able to reduce the extent of sub-cooling and the risk of tube freezing in winter.

5. Weld seam position

The weld seam is on the arc of the base tube of the single-row tubes, The arc spray aluminum coating has the better welding strength.

Shuangliang no need to be worried about the leak occurring during the operation since it can be repaired immediately without removing the entire tube bundle or replacement. Above all, we do believe in Easy maintenance and low maintenance costs.

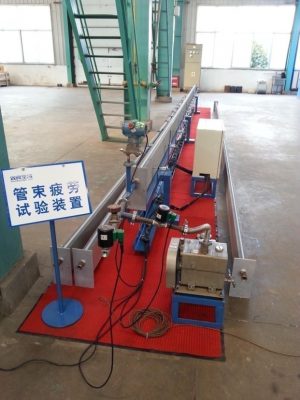

6. Single-Row Tube Bundle Fatigue test

Evacuated by vacuum pumping, the tube bundle will be reached to vacuum condition and then returned to normal pressure. After that, cycle tests will evaluate the number of cycles (fatigue life) in which the change occurs abruptly in the single-row tube.

To ensure reliance of Shuangliang Air cooled condenser (ACC), the qualified value of the product fatigue life should be more than 1,000 times and more than ten times the actual fatigue times. Due to qualified value, our customers can assure that our product’s safety lasts the 30-year design life.

THREE MAJOR TEST DEVICES

1. Performance testing device on tube bundles of Air cooled condenser (ACC)

The Performance testing device on tube bundle as applies for experimenting heat exchange performance of various types of fined tube bundle structure and online random test of finished products.

After pressure and temperature of the steam are gradually reducing, the testing device will simulate several operating backpressures of the steam turbine, measure the heat exchange performance and resistance loss of the tube bundle. It also obtains the heat exchange coefficient and air resistance of tube bundle at different air speed and internal flow resistance of tube bundle at different steam flow speed.

Furthermore, to evaluate actual performance of tube bundle, the testing device is also utilized for examining thermal performance of tube bundle.

2. The unique environmental test laboratory : 1×4 Air cooled condenser (ACC) environmental test device

Shuangliang Air cooled condenser is available for worldwide. It can simulate the summer operating conditions and winter operating conditions of Air cooled condenser (ACC), the unique environmental test laboratory will imitate ambient temperature of 50°C~-25°C. Therefore, there are two operating conditions to test in different situations.

One is the summer operating condition. It’s for testing the heat transfer performance of the tube bundles of the Air cooled condenser (ACC) which provides the basis for the design of the actual Air cooled condenser (ACC).

The other is the winter operating condition. It is for evaluating whether the control program of Air cooled condenser (ACC) is valid for antifreeze protection measures during operating conditions such as the machine functional of start, stop and low load operating conditions. Finally, it could test the minimum antifreeze steam flow under different temperature conditions.

3. The unique large full-performance test bed: Hot-state test device for one unit of 1000MW Air-cooled condenser (ACC)

The unique large full-performance test device can simulate the main operating conditions of power station for the performance test, heat exchange performance, system reliability, stability, and economy of Shuangliang Air Cooled Condenser (ACC). Particularly ensure the ACC can operate capacity at summer full load and winter anti-freezing running reliability.

Shuangliang Air cooled Research and Development

Achieving the great leap of Air cooled condenser (ACC) for power plants from theoretical R&D to engineering application isn’t an easy thing. To solve several errors in our industry, we conduct nine fundamental research to provide design support for Air cooled condenser (ACC) for power station. Therefore, It’s more suitable for Global market.

- Experimental Research on heat exchange performance of heat exchange component

- Experimental Research on resistance characteristic on air side of heat exchange component

- Investigation on resistance characteristic on steam side inside the tube of heat exchange component

- Experimental Research on atmospheric corrosion resistance of fins

- Fouling performance test of tube bundle

- Cleaning test of fins of tube bundle

- Experimental Research on freezing protection of tube bundle

- Experimental Research on computer numerical simulation of Air cooled condenser (ACC)

- Experimental research on fatiguing test of tube bundle

Shuangliang Air Cooled Condenser Reference in Power Plant

Shuangliang has received the letter of award (LOA) from Singapore ST Marine. It’s about the award of bidding for air-cooled condenser in TUAS IWMF garbage power plant project. It is planned for two phases, each phase to generate 2 X 65 MW power with waste treatment capacity to be 2,900 tons/day. In conclusion, when the project is completed, it will be the largest garbage incineration power plant in Singapore and even in whole Southeast Asia.

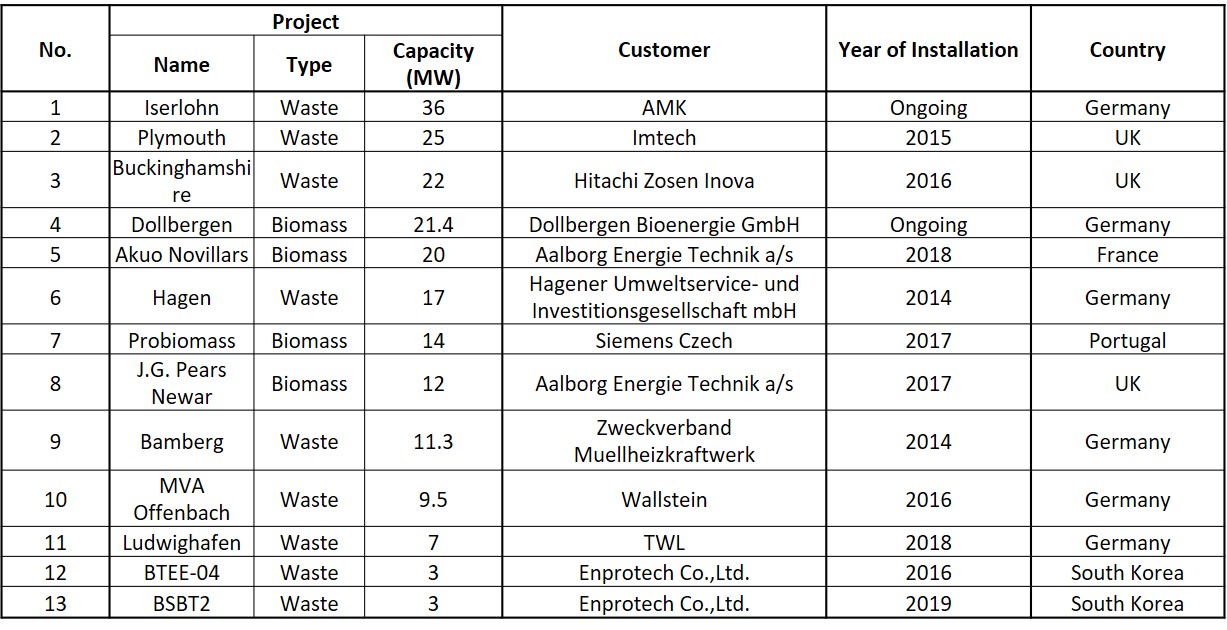

References in biomass power plant and solid waste power plant

Reference in Thermal Power Plant

- Air -cooled condenser Project for Siemens 4×1200MW New Capital CCPP in Egypt ( ACC for the largest CCPP in the world)

- Botswana project (4×150MW)

- Guohua Dingzhou Power Plant in Hebei Province (2×660MW)

- Hulunbeier Power Plant (2×600MW)

- Wison Cathay Power plant for 1 × 60,000 ASU of Wison Cathay

- Air -cooled condenser unit for 4×60,000 ASU of Zhongmei Yulin Energy Chemical Co., Ltd.

- Air- cooled condenser for 4×60000 ASU for coal-to-alkene project of Shenhua Baotou Energy Co., Ltd.

- China Coal Tuke Energy Chemical Project for 2×40,000 ASU of China Coal Tuke Energy Chemical Co., Ltd.

- Air- cooled condenser for 4 × 48,000 ASU of Datang Keqi Coal-to-Gas Co., Ltd.

- Air cooled condenser unit for 1 × 35,000 ASU of Shenhua Yulin Energy Co., Ltd.

-

Zero Water Consumption CHP System (ZWCCHP) in LATAM market

Shuangliang’s team

Our Team in Germany

In October 2014, Shuangliang Clyde Bergemann Co., Ltd. was established in Germany and is the research and development center of Shuangliang Eco-Energy in Europe. The air cooling team of Shuangliang Clyde Bergemann Co., Ltd. is composed of senior industry experts, and the core personnel industry experience is more than 30 years. Moreover, Two of them are the most authoritative German VGB air-cooled island performance test standards drafters in the world air-cooling industry. German VGB guide is the most authoritative air-cooled island performance test standard recognized by the world air-cooling industry.

Our Team in Hungary

In 2016, Shuangliang established a joint venture with Hungarian Bihong Engineering Co., Ltd. to establish Jiangyin Shuangliang Bihong Steel Structure Engineering Technology Co., Ltd. Therefore, our company can enhance the design and engineering capabilities of Shuangliang air-cooled steel structure.

Shuangliang’s Awards

2017 “China Grand Award for Industry” for the first time

It is known as the “Oscar” award of Chinese industry. We are the only enterprise winning the award in the industry of energy-saving and environmental protection

2020 China Grand Award for Industry for the 2nd time

Above all, we are the only private enterprise to win both the Enterprise Award and the Project Award.