Overview – High-efficiency Phase Separation Internal

-

Compact and robust technology lowers cost

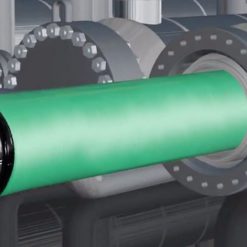

Our robust, High-Efficiency phase separation internal is used in scrubber vessels, two- and three-phase separators, free-water knockout drums, flare knockout drums, contactor towers, and slug catchers to improve separation of oil, gas, sand, and water.

Designed to meet the most stringent demands for separation performance in a compact space, high-efficiency phase separation internal improves separation effectiveness at very high operating pressures. Also, they enable reductions in pressure vessel size and weight, and hence, required floor space and protect the downstream process system from contamination.Futhermore, the internals reduce the need for chemicals such as defoamers and demulsifiers and maintain high separation efficiency under turndown conditions.

By helping to capture the free liquid in the gas stream, these internals minimize loss of liquid hydrocarbons or glycols. They are also valuable for retrofitting existing vessels to achieve increased capacity or better performance.

-

Use separation volume efficiently

Operators are continuously looking to improve efficiency and reduce overall costs. In-vessel compact separation enables more efficient use of separation volume compared with traditional gravity separation vessels. Our high-efficiency phase separation internal further enhances this efficiency by using centrifugal, capillary, or electrostatic forces rather than just the force of gravity to decrease separation time; reducing separation distances; and employing perforated plates in separators and mesh pads in scrubbers.

Application of High-efficiency phase separation internal

-

CONSEPT ACI axial cyclonic inlet device

- High-efficiency centrifugal inlet device for scrubbers

- Bulk separation vessel to be installed as an inlet in scrubbers

- High-pressure applications and compact vessels

- Retrofitting to increase gas load or separation performance

- Retrofitting using only cold work

- Removal of more than 90% of the liquid already in the vessel inlet at K values up to 0.5 m/s

Our CONSEPT ACI* axial cyclonic inlet devices are highly efficient for removing small amounts of liquid from a gas stream, achieving close to 100% efficiency at a wide range of flow rates. Axial flow cyclone efficiency is important to achieving the stringent separator performance of 0.1 galUS/MMscf that typically is required. The latest generation of CONSEPT ACI devices incorporates a new element in the existing cyclone, reducing the liquid carryover by a factor of 10. The increased separation efficiency enables vessels to be more compact, which is especially advantageous for high-pressure and subsea applications

-

CONSEPT IVD separator inlet vane diffuser

- Vane inlet used in separators and scrubbers

- Retrofitting and installation using only cold work

- High-pressure applications

- Good hydraulic performance and stable flow in the inlet section

- Enhanced liquid separation inside the vane inlet

The CONSEPT IVD* separator inlet vane diffuser consists of multiple dual-plate vanes that effectively distribute gas and liquid. These vanes are designed to avoid any liquid carryover with gas by providing gradual bend and enough surface area for liquid to separate from gas.

The diffuser vanes are more efficient compared with single-plate vanes, which include a 90° bend and can potentially carry over excess liquid with gas. Installing an CONSEPT IVD diffuser on the inlet section of the separator uniformly distributes gas and liquid to decrease the required residence time for the separator while maintaining the required separation efficiency.

-

CONSEPT DC demisting cyclones

- Highly efficient cyclonic demisting

- Operations with scrubbers, separators, and contactor towers

- Operations with high pressures and low surface tensions

- Retrofitting

Schlumberger CONSEPT DC* demisting cyclones are compact cartridges of minicyclones that remove liquids from gas. Each cyclone is designed with internals that set fluids into centrifugal motion to separate liquid from gas. Several of these cyclones are combined and installed on the gas outlet of the separator.

Demisting cyclones provide a higher K value compared with standard demisters or a mesh pad. In combination with other internals, the CONSEPT DC cyclones can increase separation efficiency of the separator to remove 99.99% of 10-um-or-larger liquid droplets or 0.1-galUS/MMscf liquid carryover.

-

PORTA-TEST REVOLUTION separator internal

- Cyclonic inlet

- Inlet device for two- and three-phase separators

- Reduction of foam in vessel by separating gas and liquidsbefore inlet momentum reduction

- Accommodation of high inlet momentum in vessels

- Elimination of scaling effects through use of multiple tubes

- Special design for two- and three-phase vessels

The PORTA-TEST REVOLUTION* separator internal is a unique separator internal inlet device used to eliminate foam and improve fluid management within the separator. The separator internal can be connected directly to the inlet nozzle during fabrication, or it may be installed as a retrofit through a maintenance hole. It is suitable for use in both vertical and horizontal vessels. With more than 500 installations worldwide, we have the experience and expertise to optimize your separator performance.

-

Contactor vessels with demister integrated in chimney tray

Our unique contactor design has a built-in inlet and outlet gas scrubbing system, which can potentially eliminate the requirement of scrubbers upstream and downstream of the contactor. The inlet section of the contactor can be equipped with the CONSEPT IVD separator inlet vane diffuser, which provides uniform distribution of the gas and removes any entrained liquids. The outlet section of the gas, from the top of the contactor tower, uses a CONSEPT DC demisting cyclone as the demisting section, increasing the overall separation efficiency and reducing the solvent losses with outlet gas. The demister for the hydrocarbon scrubber is fitted inside the chimney tray to save space. The pressure drop through these devices is much less compared with individual scrubbers, providing overall capex and opex savings.

-

Robust three-phase separation with mechanical coalescence

The three-phase separator is designed with various internals for fluid inlet, gas outlet, and liquid outlet to provide higher separation efficiency while potentially decreasing the overall size of the vessel by reducing the overall required residence time. These three-phase separators are designed to handle oil, gas, produced water, and solids. To improve the separation performance, Schlumberger uses its high-efficiency separator internals— CONSEPT IVD diffuser, CONSEPT DC demisting cyclone, PORTA-TEST REVOLUTION separator internal—vortex breakers, or NATCO PERFORMAX* horizontal high-efficiency phase separator to ensure mechanical coalescence and improved separation.

Project Reference

Arthit

- Unicel, Vertical Induced Gas Flotation Unit A4000

- Removing oil and suspended solids from produced water

- Desanding Hydrocyclone + Accumulator A-4000

- Removing sand and other solids particles from produced water

- Sea Water Filter (F4650 F4655 F4660)

- Removing suspended solids from sea water

- Coarse Strainer Sea-Screen

- Filtration to protect downstream equipment

Bangkot

- Sea Cell’ Sodium Hypochlorite Generator (2×030 cells, 0.3 kg/h)

-

- Sea water treatment

- Desanding Hydrocyclone

-

- Removing sand and other solids particles from produced water

- ANSI Class#300

- Dasander Type: 16-300-CP2

- 10,000×2 BWPD

- Deoiling Hydrocyclone

-

- Cyclotech PECT-F & B20 Deoiling Hydrocyclone Field Trial

Sirikit S1

- NATCO Flotation Cells

- Removing oil and suspended solids from produced water

GBS – 2023

- Horizontal Cynara Membrane Elements (8”) for CO2 Removal System

-

Chevron

-

- Cameron Process System

| ASSET | TYPES OF PACKAGES/EQUIPMENT |

| Funan | NATCO Glycol Dehydration Unit |

| NATCO Separator Internals | |

| (Consept IVD-Gas scrubbing / separation) | |

| Jakrawan | L/L Hydrocyclone |

| (7400 BPD) | |

| Desanding Hydrocyclone | |

| – ANSI Class#300 | |

| – Dasander Type: W6U/CP1-M37 | |

| -5×60,000 BWPD | |

| Desanding Hydrocyclone | |

| Platong | Electrostatic Coalescer |

| Desalters | |

| NATCO Separator Internals | |

| Consept IVD Gas scrubbing / separation) | |

| Palin | CO2 Removal Unit, Cynara Membrane |

| NATCO Flotation Cells | |

| L/L Hydrocyclone (L15 Liner, 16800 BPD) | |

| Desanding Hydrocyclone | |

| – ANSI Class#150 | |

| – Dasander Type : 24-300-CP2 | |

| -30,000×2 BWPD | |

| Funan | NATCO Glycol Dehydration Unit |

| Wemco Depurator (Flotation cells) | |

| L/L Hydrocyclone (L15 Liner, 30,000 BPD) | |

| Inlet Separator | |

| Production Compressor Suction Scrubber | |

| Cold Separators | |

| Pipeline Compressor Suction Scrubbers | |

| Benchamas | Hydromation Nutshell Filter |

| Liquid Hydrocyclones (Produced Water) | |

| 2 x Produced Water Packages | |

| (Hydrocyclone + Degassing Drum) | |

| IGF | |

| Erawan | NATCO TEG Reboiler/Surge |

PTTGC – 2023

Mesh Pad and PERFORMAX Structured Packing for 2-Phase Separator Including

- (1) x 82-1/4″ OD x 4″ Thick Wire Mesh Mist Pad, 9# Density, 304SS Material with 1″ top and bottom SS Grids, 12 sections

- (3) x 82-1/4″ OD x 11-3/8″ Thick Coalescer Plate Pack, 304SS Material Full Diameter CPP, 12 sections, 304SS Shroud Wrapped Outer Edge of Packing

ESSO Sriracha Refinery (EXXON) – 2021

- Electro-Chlorinator METROL SEA-CELL

- Model: 120 sea-cell

- Plate coating: KMHT

- Bolting material: 316SS

- NEW CELL CL-1602

- Part Number: 7AA004SE00E7800201

Mubadala Petroleum – Nong Yao

- EPCON CFU Package (Compact Flotation Unit)

- Production Separator Retrofit (2017) : To enhance liquid separation. Concept IVD, plate pack coalesce and perforated plates

PTT/UAC Rayong – 2011

Retrofit of KO Drum. ACI, Mesh pad and DC56

TOTAL – Bongkot

- Deoiling Hydrocyclone

Brochure

Download