Overview of PERFORMAX*

PERFORMAX*

PERFORMAX* Matrix Plate Coalescer was first introduced by NATCO.

The PERFORMAX* coalescer was designed to replace the traditional horizontal freewater knockout drum as the primary oil-water separator. Most of the oil-water separation occurs within the coalescing section near the front of the vessel. This enhanced oil-water separator requires less length downstream for the effective separation.

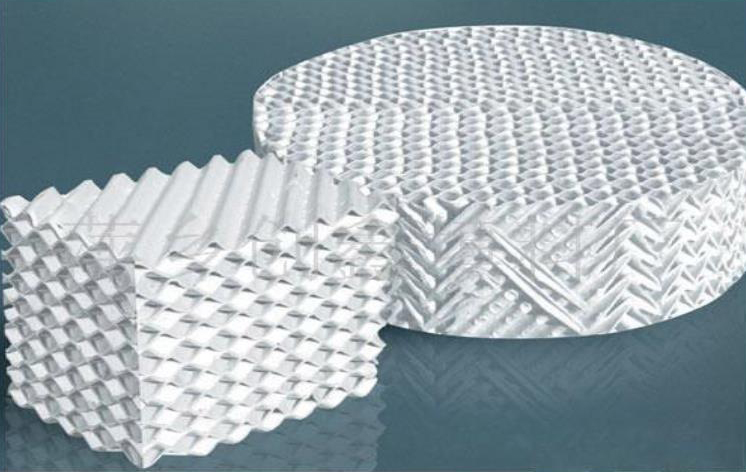

PERFORMAX* coalescing plate pack is manufactured from various materials, such as stainless steel 304, and 316, depending on the operating conditions

We have applied it for horizontal high-efficiency phase separator to ensure mechanical coalescence and improved separation.

Application of PERFORMAX*

The PERFORMAX* coalescing plate pack has been useful over the entire range of producing conditions, and for oil & gas industries, refineries, and petrochemical plants. The applications include;

- Oil and Water Treating Systems

- Freewater knockout drums (FWKO)

- Horizontal Longitudinal Flow Separator/ Coalescer

- Robust three-phase separation with mechanical coalescence

- Oil Dehydration Equipment

- NATCO DOX: Dispersed oil extractor system for Ethylene quench water treatment

Reference

The advantages contain;

- enhanced water and oil quality

- enhanced oil-water separation

- lower gas entrainment

- lower emulsion breaker chemical requirements

- lower fuel costs

as compared to the common industrial standard separator

Project Reference

- PTTGC – 2023

(1) x 82-1/4″ OD x 4″ Thick Wire Mesh Mist Pad, 9# Density, 304SS Material with 1″ top and bottom SS Grids, 12 sections

(3) x 82-1/4″ OD x 11-3/8″ Thick Coalescer Plate Pack, 304SS Material Full Diameter CPP, 12 sections, 304SS Shroud Wrapped Outer Edge of Packing