Overview – Glycol dehydration systems

Efficient removal of water and impurities from natural gas streams

Our triethylene glycol dehydration system is among the most widely used in the oil and gas industry because of low operating costs and relatively low capex. Glycol dehydration systems are not only efficient at removing water from a natural gas stream, they also remove benzene, toluene, ethylbenzene, and xylene (BTEX) as well as other volatile organic compounds (VOCs).

In natural gas systems, removing water vapor reduces pipeline corrosion and eliminates line blockage caused by hydrate formation. The water dewpoint needs to be below the lowest pipeline temperature to prevent free-water formation.

Using amine treatment to remove acid gases results in water-saturated gas that must be dehydrated before entering the pipeline. Most product specifications require the maximum quantity of water in the gas to be 4 to 7 lbm/MMcf.

Advantages

- Suitable for a wide range of flow, pressure, and temperature conditions

- Lower operating costs than conventional desiccants

- Lower capex than solid bed systems

- Custom and standard units, which can employ either bubble cap or structured packing

- Reduced manufacturing and commissioning times for standard system designs

- Easily packaged hybrid systems (amine packaged with glycol dehydration systems) for small to large gas sweetening requirements

Application of Glycol dehydration systems

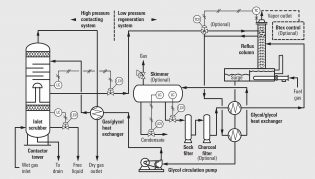

In our glycol dehydration system, wet gas enters a tower at the bottom and flows upward. Dry glycol flows down the tower from the top, from tray to tray or through packing material.

Our special bubble cap configuration maximizes gas-glycol contact, removing water to levels below 5 lbm/MMcf. Advanced systems can be designed to achieve levels less than 1 lbm/MMcf.

The dehydrated gas leaves the tower at the top and returns to the pipeline or goes to other processing units. The water-rich glycol leaves the tower at the bottom and goes to the reconcentration system, where it is filtered to remove impurities and heated to 400 degF [204 degC]. Water escapes as steam, and the purified glycol returns to the tower where it again contacts wet gas.

The entire system operates unattended. Controllers monitor pressures, temperatures, and other aspects of the system to maximize safety and efficiency.

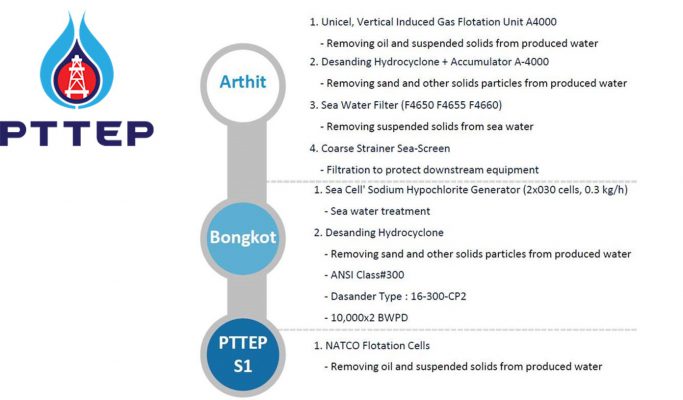

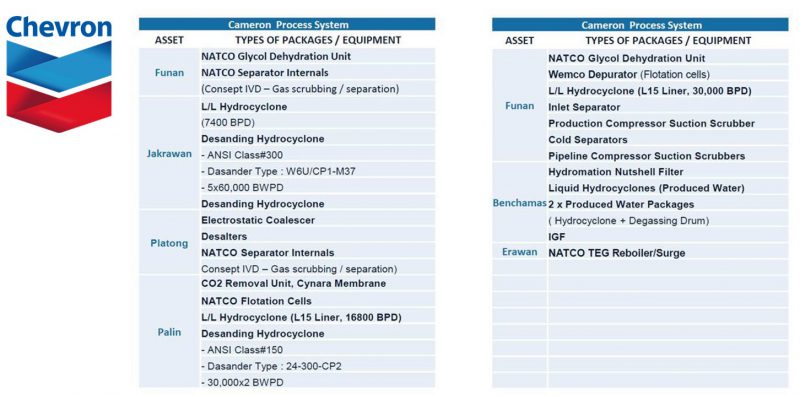

Project Refrence

Brochure

Download

Ref: https://www.youtube.com/watch?v=3AlhN5LV3zM