Overview – MOZLEY Wellhead Desander- Solids removal system

-

Eight times longer lifespan in aggressive multiphase well fluid environments

The MOZLEY Wellhead Desander Solids removal system provides unmatched performance and durability in one of the most difficult and important solids management applications: sand removal from wellhead fluids. To provide the most effective desanding and offer the best protection for equipment downstream of the wellhead, choosing the best hydrocylone configuration is key.

-

Protect process equipment erosion and downtime

MOZLEY Wellhead Desander solids removal systems mitigate the effects of sand production, such as mechanical damage to equipment; erosion of pumps, valves, chokes, and flowlines; and reduction in separator capacity due to settlement of sand. The systems use a simple, compact design based on solid-liquid hydrocyclones to separate solids from both the gas and liquid components of well fluids. The hydrocyclone housings can be customized to handle high wellstream pressures and widely varying feed conditions.

-

Choose fit-for-purpose solids removal at the wellhead

Selection of the hydrocyclone internals depends on the range of viscosities and specific gravities of the well fluids and the operating gas/liquid ratios. Proper selection ensures optimal performance throughout the operating ranges and provides equipment downstream of the desanding system with superior wear protection.

MOZLEY Wellhead Desander systems employ solid liners made of special silicon nitride ceramic material developed expressly for use in hydrocyclone liners. These liners last eight times longer than competitive alumina ceramic desanders or ceramic-coated hydrocyclones. This provides a reduction of downtime stemming from hydrocyclone wear and replacement, which lowers operating expense. Additionally, the liners are self-cleaning, and slugging of solids will not plug them, further reducing downtime and lowering opex.

-

Use multiple small hydrocyclones for greater efficiency

The core of the system is the hydrocyclone liner. Use of extensively enhanced geometrical features and specifically selected construction materials maximizes performance and minimizes erosion in aggressive multiphase well fluid environments. Multiple hydrocyclones are typically installed within a pressure vessel, providing significantly greater efficiency and operating life compared with a large-diameter single hydrocyclone or ceramic-coated metal inserts.

These hydrocyclone clusters cope with the surges of gas and liquid flows much better than large-diameter single hydrocyclones, operating instantaneously to achieve solids separation. With a single hydrocyclone, any high-concentration slugs of solids can potentially block the inlet and underflow, preventing flow.

For less-demanding separation duties, a large-diameter single liner—typically 10-in diameter or greater—can be used. Packaged in a vessel, the single-liner design can reduce costs compared with multiple liners.

Application of MOZLEY Wellhead Desander- Solids removal system

The cyclone inserts of the MOZLEY Wellhead Desander system are specifically designed for each application using proprietary computer simulations. The silicon nitride ceramics developed expressly for used in the solid ceramic hydrocyclone liners deliver 8 times greater wear resistance, as compared with standard grades of ceramic liners or ceramic-coated hydrocyclones. Wellstream fluids enter the cyclone tangential inlet, which forces the mixture to spin and in turn causes the gas to disengage quickly. Both gas and liquids migrate toward the center of the cyclone, as a reduction in cyclone diameter accelerates the fluid while concurrently generating strong centrifugal forces. The gas and liquid flow then reverses and moves upward toward the overflow vortex finder. Solids are separated from the gas and liquid, forced toward the cyclone wall, where they travel down the length of the conical section of the cyclone in a spiral pattern to the solids outlet. The separated solids fall through into the accumulator vessel situated on the underflow of the wellhead desander, or a continuous hydrotransport device can be used. The accumulator vessel is periodically isolated and collected solids are flushed out. The wellhead desander itself remains online and operating while the accumulator is being cleaned.

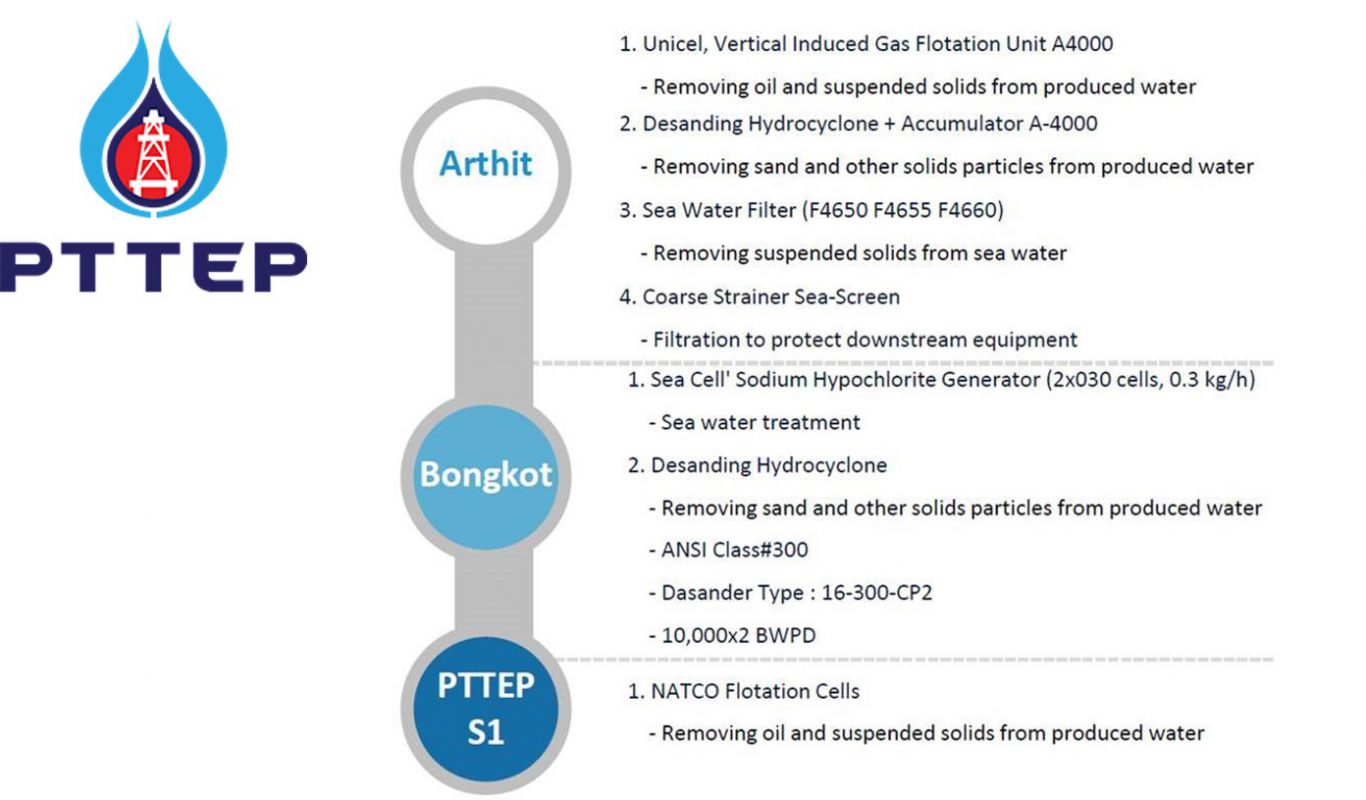

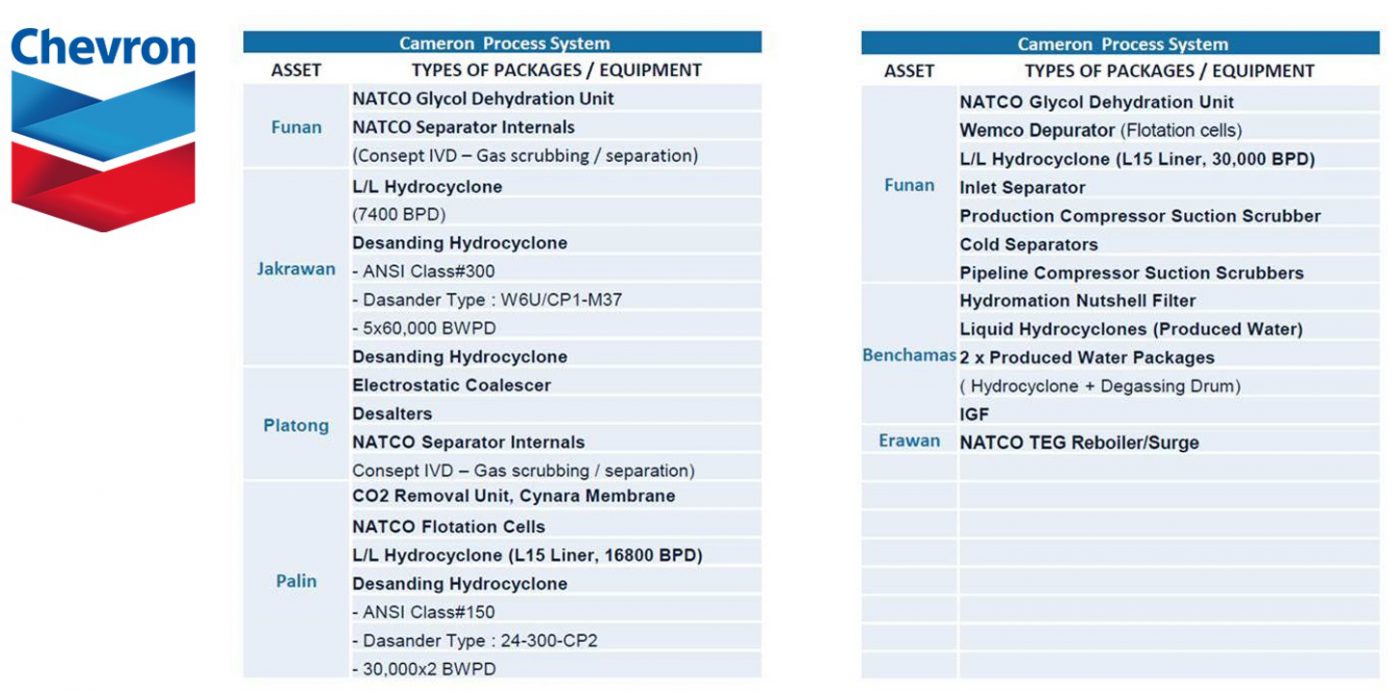

Project Reference

Brochure

Download