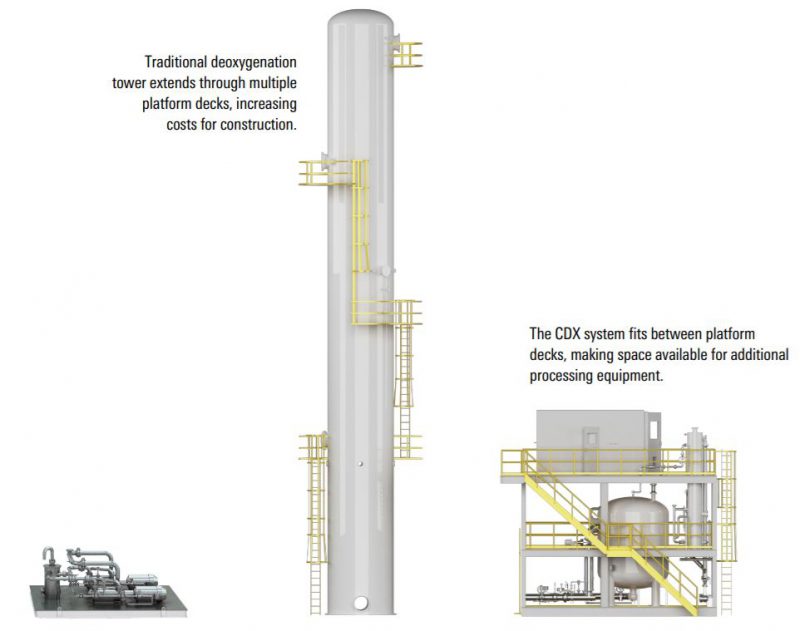

The Schlumberger CDX Compact Deoxygenation System enables removing oxygen from seawater in a footprint that is upto 40% smaller and 60% lighter compared with conventional systems.

Overview – CDX Compact Deoxygenation System

-

Use seawater for EOR, even with limited space

Oil and gas field development is moving to new frontiers, including deeper waters offshore. Operators are also expected to make greater use of enhanced oil recovery (EOR) techniques, including seawater or controlled-salinity water injection.

Like injection pipelines, downhole tubing is usually unlined carbon steel and is highly susceptible to corrosion from oxygenated seawater. Therefore, removing the oxygen from seawater that is to be injected is essential for EOR operations.

-

Compact alternative to traditional vacuum towers

Traditional processing equipment has included vacuum and gas-strip deaeration, which are bulky and have high input requirements. Recognizing the need for robust and compact, less resource-intensive solutions, we developed the CDX compact deoxygenation system.

This proprietary, self-contained, and lightweight seawater deoxygenation technology employs hydrogen and a catalyst to strip oxygen from seawater. The hydrogen is injected into the feedwater and passed over a catalyst bed, where the dissolved hydrogen reacts with oxygen to produce water for injection into the reservoir.

-

Get the most out of your facility with a compact, catalyst-based deoxygenation system

Using a chemical reaction process employing a catalyst has several advantages over a mass transfer process, which requires a packed tower.

- Reduced chemicals. The CDX system delivers single-digit parts-per-billion oxygen and chlorine outlet concentration without the need for scavenging chemicals.

- No tower required. The CDX system uses a small reaction vessel, a design that reduces the system in height, footprint, and weight. The system can easily fit between decks, meaning a simpler facility design and the elimination of deck penetrations.

CDX systems operate flooded at pressures of at least 4 bar above atmospheric pressure. This means dynamic motion performance issues and any antifoam requirements are eliminated, as could the need for booster pumps, depending on the application.

The only utility requirements for the CDX system are power and potable water. To safeguard the CDX system from inorganic and organic fouling, pretreatment of the seawater with a membrane separation process is required. The system can employ the Polymem UF seawater ultrafiltration system or our sulfate removal system.

Application of CDX Compact Deoxygenation System

The CDX system treats incoming seawater by first measuring it with a flowmeter, which produces a flow rate value that is registered by the system’s controls. Based on this value, the system produces and injects a proportional amount of hydrogen gas into the water upstream of the system’s inline mixer. The mixer ensures the dissolution of the hydrogen into the water. The resulting water-hydrogen mixture is then routed to the catalyst vessel, where it contacts the palladium catalyst. Once there, the oxygen in the water reacts with the dissolved hydrogen, producing water with oxygen levels that are below 10 ppb and suitable for reservoir injection.

Project Reference