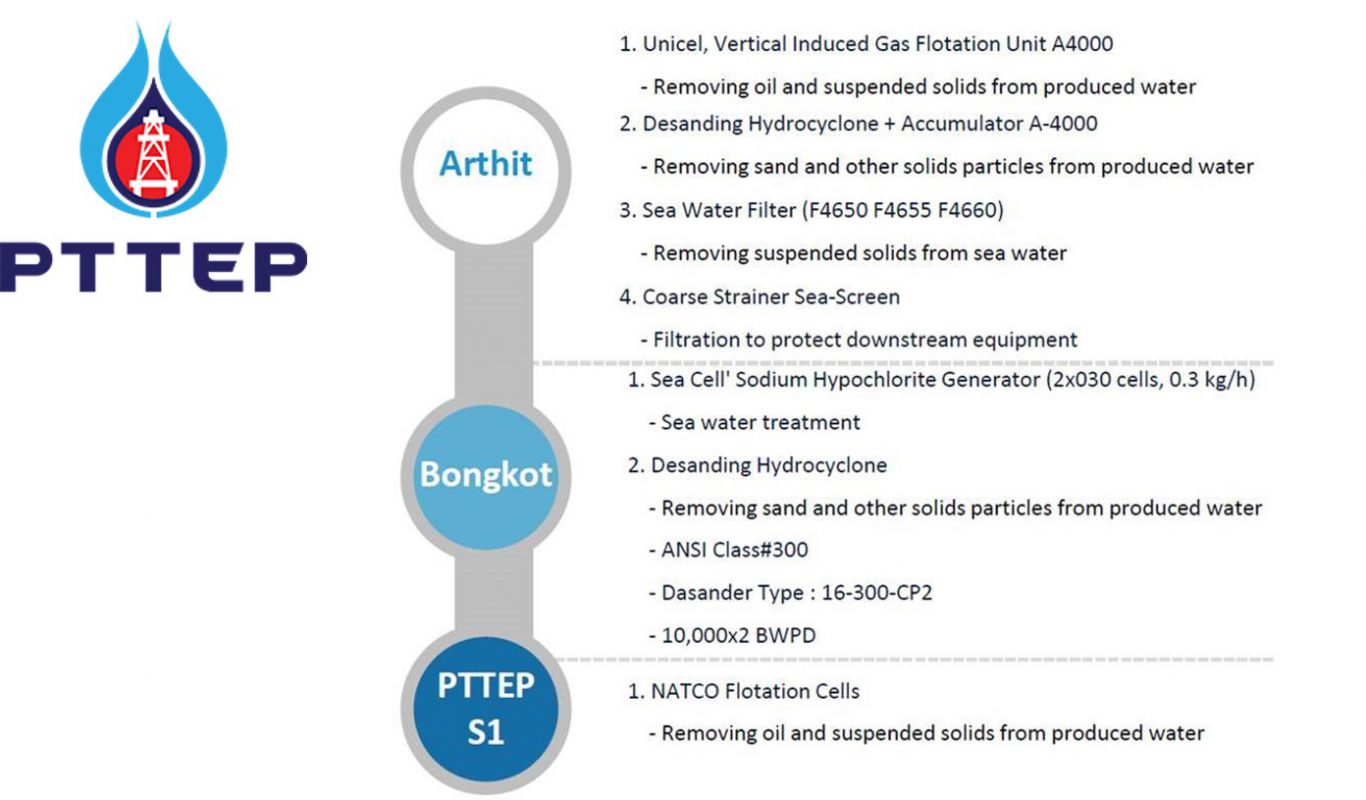

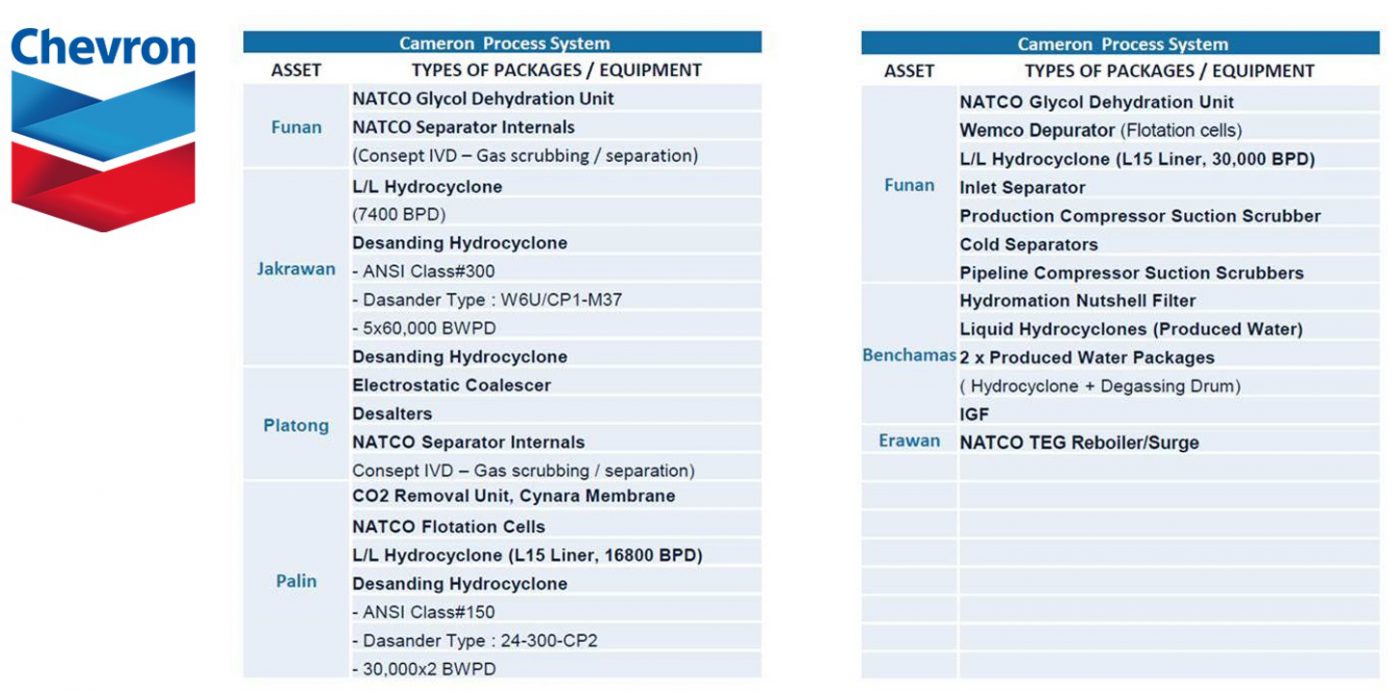

To complete our current membrane technologies in sulfrate reduction and seawater RO,Sclumberger offers Polymem UF Seawater Ultrafiltration System to the oil and gas industry.We are the exclusive provider of Polymem® UF system to the oil and gas industry, for which Polymem SA,France, is the developer and manufacturer of the UF membrane elements.

Overview – Polymem UF Seawater Ultrafiltration System

-

More efficient filtration of solids down to 0.01 um

Solids suspended in seawater must be removed before use in many oil and gas applications, particularly if seawater is going to be injected into the reservoir. Minerals contained in seawater can react with reservoir chemistry, which can cause production problems. In addition to reservoir requirements, process equipment used in a seawater treatment system can also dictate the necessary level of suspended solids removal.

-

Consistent seawater filtration performance

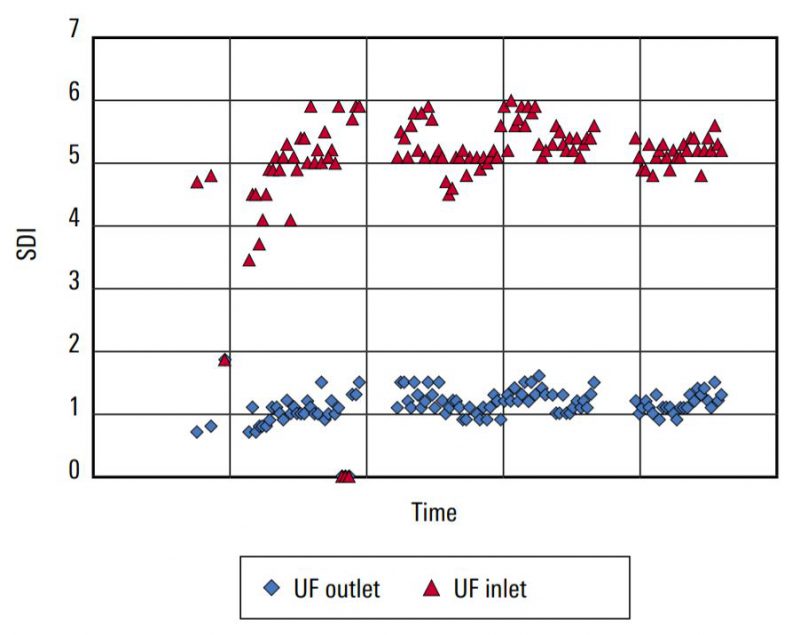

Polymem UF seawater ultrafiltration systems remove suspended particles as small as 0.01 um from seawater and can replace media filters and cartridge filters. They provide significant weight savings compared with media filtration and lower total life-cycle cost compared with stand-alone cartridge filtration, independent of varying feedwater quality.

The space-saving Polymem UF design is more compact than other ultrafiltration or microfiltration designs for an equivalent filtration surface. Filtration down to the 0.01-um level includes the removal of all suspended organic components. This is an extremely clean product water passed to downstream systems, which can improve run time and reduce operator intervention.

-

Cost savings

Overall, the efficient removal of particulates by membrane separation can reduce the risk of lost and deferred production. Considerable weight is saved when UF is used compared with media filtration systems. The operational costs are reduced due to the elimination of cartridge filter replacement.

Application of Polymem UF Seawater Ultrafiltration System

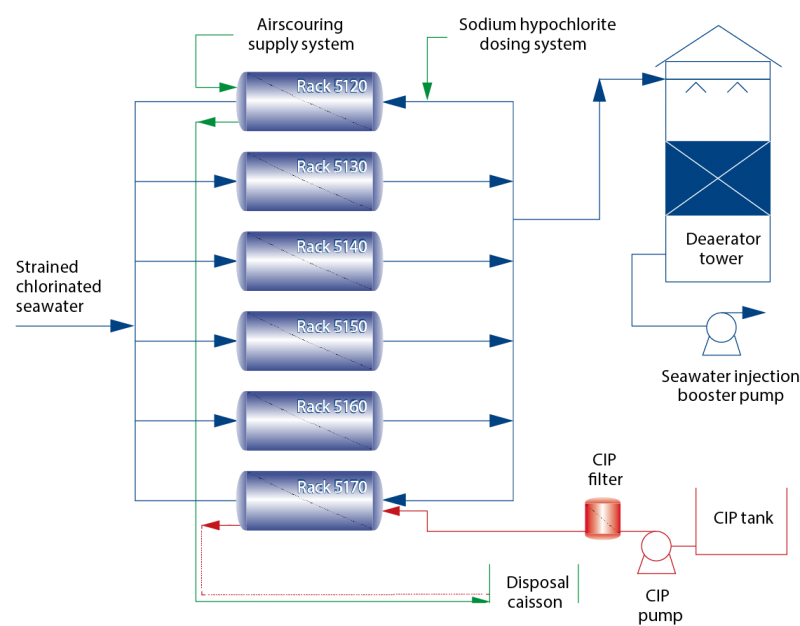

During normal operation, the suspended material in the feedstream is retained on the membrane surface as a cake. At a predetermined interval, automatic cleaning procedures are performed to remove the cake and restore clean performance. Offline cleaning-in-place (CIP) packages are also provided. CIP packages typically are designed with redundancy so that the specified design permeate output can be maintained during backwashing, cleaning, and routine maintenance. For deepwater intakes where suspended solids content is very low, the normal system flux is around 1.96 galUS/ft2 /h [80 L/m2/h] when data are normalized at 68 degF [20 degC]. Normal operation assumes that one rack is offline and another rack is in backwash mode.

Project Reference

Brochure

Download