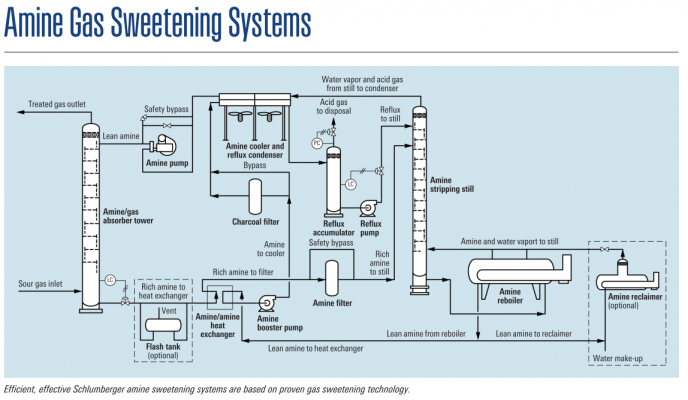

Overview – Amine gas treating systems

-

Prepare natural gas for commercialization

Custom and standard Amine gas treating systems remove CO2 and H2S, resulting in gas with <2-mol% CO2 and <4-ppm H2S. Efficiently removing CO2, H2S, and mercaptans makes the gas suitable for transportation and use.

The amine plant can be installed as a stand-alone component or as a part of an integrated processing system. We can custom engineer solutions for amine recirculation rates above 700 galUS/min [2.64 m3/min], and we offer five standardized designs for rates below 700 galUS/min. Years of gas sweetening expertise is built into the design and engineering of our standardized gas plants. So you can expect to achieve performance comparable to a custom-designed sweetening plant.

-

Amine treating advantages

- Various heat sources (direct-fired, waste heat, hot oil, and steam systems) can be used for the still reboiler.

- Customized plants can be designed to customer specification while maintaining fast delivery.

- Our amine systems can meet required CO2 and H2S levels operating with multiple solvent types and recirculation rates.

- Standard system designs reduce manufacturing and commissioning times.

- Amine systems are easily combined with other technologies into hybrid systems for many sizes of gas sweetening projects.

Application of Amine gas treating systems

Amine sweetening process as following:

- Sour gas enters the contactor tower and rises through the descending amine solution.

- Purified gas flows from the top of the tower.

- The amine solution, carrying absorbed acid gases, leaves the tower for the heat exchanger or optional flash tank.

- Rich amine is heated by hot regenerated lean amine in the heat exchanger.

- Rich amine is further heated in the regeneration still column, by heat supplied from the reboiler.

- Steam and acid gases separated from the rich amine are condensed and cooled, respectively, in the reflux condenser.

- Condensed steam is separated in the reflux accumulator and returned to the still. Acid gases may be vented, incinerated, or directed to a sulfur recovery system.

- Hot regenerated lean amine is cooled in a solvent aerial cooler and circulated to the contactor tower, completing the cycle.

- A variety of heat sources can be used for the still reboiler—direct fired, waste heat, hot oil, and

steam systems.

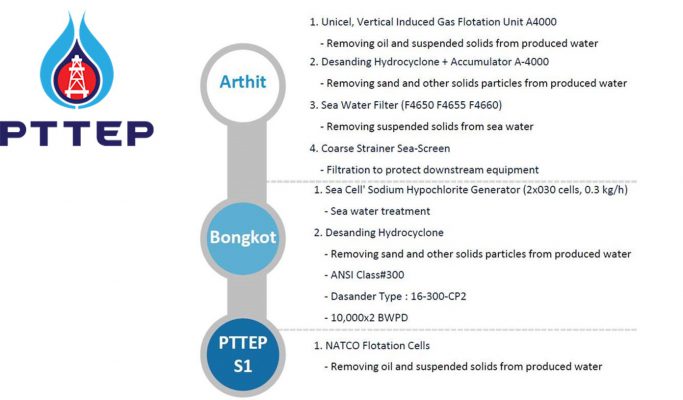

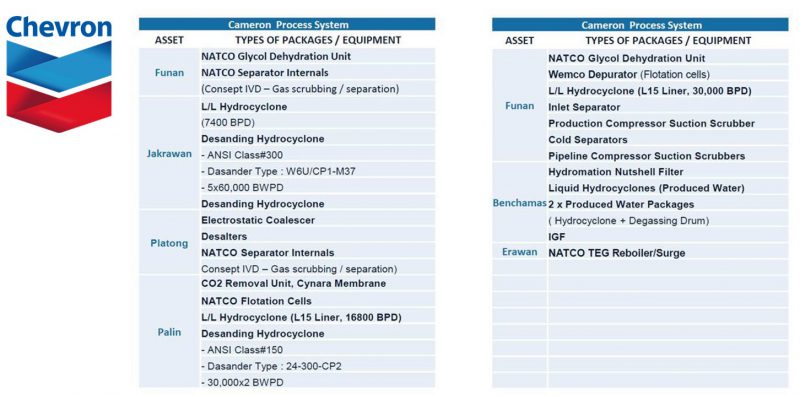

Project Reference

Brochure

Download