Overview – VORTOIL Deoiling Hydrocyclone

-

Benefit from over three decades of field-proven experience

VORTOIL Deoiling Hydrocyclone incorporate more than 35 years of continuous development and operational experience, resulting in a highly efficient, compact, and inexpensive method of removing oil from large volumes of produced water. They remove the bulk of the free oil content (typically everything with a particle size greater than 10 to 20 um) in a produced water stream to reduce the load on downstream treatment processes.

The central feature of our Deoiling Hydrocyclone is the internal geometry of each liner design, developed to provide high separation efficiency. Liner installation options that also increase the liner packing density are available, further reducing the package footprint and weight.

The VORTOIL hydrocyclone’s elegant yet functional design results in operational simplicity and extremely low maintenance. There are no moving parts inside the vessel, and construction materials have been carefully selected to resist erosion. A variety of options are available for flow turndown, including the use of blank liners and multicompartment vessels.

-

Special features :

- <98% separation efficiency

- Compact, lightweight installation

- No internal moving parts and minimal power requirements

- Individual flow rates from 1,000 to >160,000 bbl/d [160 to >25,400 m3/d]

Application of VORTOIL Deoiling Hydrocyclone

Produced water is fed into the VORTOIL Deoiling Hydrocyclone through single or dual tangential inlets. This promotes high fluid spin within the hydrocyclone head, resulting in the rapid formation of a stable free vortex.

As the fluid moves down the length of the hydrocyclone liner, centrifugal forces cause the denser water phase to concentrate at the outer diameter while the lighter hydrocarbon phase collects in the center of the liner. With the correct pressure settings, it is possible to bring about an axial reversal of the central oil core.

The low-density oil-enriched phase can be removed from the center of the hydrocyclone head as the reject phase while the bulk of the liquid, including residual contaminants, flows out of the tail section as the underflow.

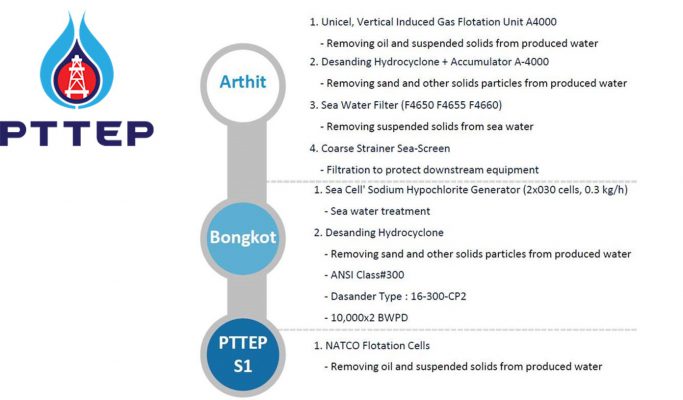

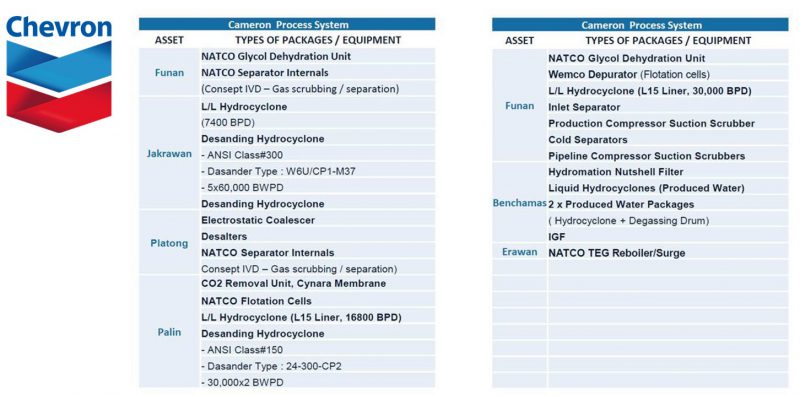

Project Reference

Brochure

Download