Technological Excellence

- Mechanized Epoxy Powder Feeding System

- On-line monitoring and recording by Optical Pyrometer and Chart Recorder

- Automatic OD Coating Stripping Line (offline)

- Environmental friendly High Volume Bag Filters with Dust emission Levels less than 20mg/Nm3

- 4000kW High-Frequency Induction Heat System

- 125 Feet Long Cooling Tunnel with Stainless Steel Troughs designed for uniform laminar flow of water

- Efficient Curing Chamber at Internal Lining with mechanized feeding to External Coating Line

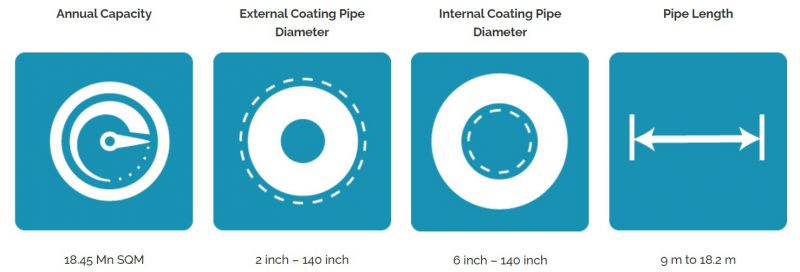

External and Internal Pipe Coating

Coating Product Range

- 3 Layer Polyethylene / Polypropylene Coating.

Complying ISO 21809-1, DIN 30670-12, DIN 30678-13, CSA Z.245.21-Series-14, NF49 710, NF49 711 and Client Specification

- Fusion Bonded Epoxy (Single / Dual layer) coating.

Complying CSA Z 245.20 Series -14, NACE SP 0394-13, ISO 21809-2 and Client Specification

- Internal Flow Epoxy Coating.

Complying API RP5L 2, ISO 15741 and AWWA C210

- External and Internal Bend Coating.

Complying EN 10290, API RP5L 2, ISO 15741 , AWWA C210 and Client Specification

- Concrete Weight Coating

Complying ISO 21809-5, AWWA C 205, DNV-OS-F101 and Client Specification