We can see 5 key differences between them, namely insulation material, temperature resistance, flexibility, durability and electrical properties. However, before we are going to talk about the differences, we need to know about the story behind the solar cable invention first. It’s the year 2022, and companies in India and around the world are all about going green. If you’re thinking of slapping some solar panels on your rooftop, that’s awesome – they’re super beneficial for the environment. But here’s the catch: you need special wiring for that, and that’s where solar cables come into play.

Do you know about Solar cable, and how it differs from normal cable?

Solar cables are the ones that link up your solar panels with other electric stuff in a photovoltaic system. You need to be sure that the electricity will get where it needs to go when the solar panels are producing electric power from the sunlight. However, solar cable is not the same thing as normal cable. As we talked about eco-friendly points, solar panels are more green than normal ones.

A solar cable consists of multiple insulated wires and serves the purpose of connecting various components in a photovoltaic system. One significant advantage is their resilience to harsh weather conditions, extreme temperatures, and UV radiation. The cable’s diameter increases with the number of conductors it contains.

There are two main types: solar DC cable and solar AC cable, representing direct current and alternating current variations. Solar DC cables come in three sizes – 2mm, 4mm, and 6mm in diameter – and can be either module cables or string cables. When choosing a solar cable size, it’s advisable to opt for a slightly larger and higher voltage than what’s strictly required. The quality of a solar cable is gauged by factors like resistance, ductility, malleability, heat capacity, dielectric strength, and freedom from halogen.

Let’s talk about the differences between solar cable and normal cable.

One of the primary disparities lies in the insulation material utilized. Solar cables, meticulously crafted for the unique demands of photovoltaic systems, boast insulation made of cross-linked polyethylene (XLPE) or ethylene propylene rubber (EPR). This design is a response to the formidable challenges posed by the sun’s ultraviolet (UV) radiation and other environmental factors. Unlike normal cables that might employ insulation materials such as polyvinyl chloride (PVC) or rubber, solar cables are fortified against the deleterious effects of prolonged exposure to sunlight.

Secondly, the temperature resistance, temperature resistance is another pivotal factor that demarcates solar cables from their traditional counterparts. Solar cables are engineered to weather a spectrum of temperatures, particularly the elevated levels that can be generated within solar panel systems. This resistance to temperature fluctuations is vital for the sustained performance of cables in solar installations, where varying environmental conditions are the norm. The materials used in solar cables confer upon them a higher threshold for heat, ensuring that they remain steadfast even in the face of the thermal challenges inherent in solar power generation. In contrast, standard cables may not possess the same degree of temperature resistance, making them less suitable for the demanding conditions encountered in solar arrays.

Thirdly, we are going to talk about flexibility. Flexibility is a characteristic that assumes heightened significance in the context of solar installations. Solar cables are designed with a keen awareness of the intricate routing and bending often required in the installation of solar panels. Their enhanced flexibility facilitates the ease of installation, allowing them to navigate through tight spaces and intricate configurations with minimal hassle. On the other hand, normal cables, while having a range of flexibility characteristics depending on their intended use, may lack the optimized flexibility needed to navigate the unique challenges posed by solar installations.

Fourthly, durability and outdoor performance are paramount considerations in the selection of cables for solar applications. Solar cables, cognizant of their role in outdoor environments, are crafted with materials that endow them with robust durability. Exposure to sunlight, rain, and other environmental elements is an inevitable part of the life of a solar cable. Hence, the materials used in their construction are chosen for their resilience in the face of these challenges. The durability of solar cables is not just a matter of longevity; it directly impacts the reliability of the entire solar power system. In contrast, normal cables, which may be designed for indoor use or less demanding outdoor conditions, might not possess the same level of durability or weather resistance as their solar counterparts.

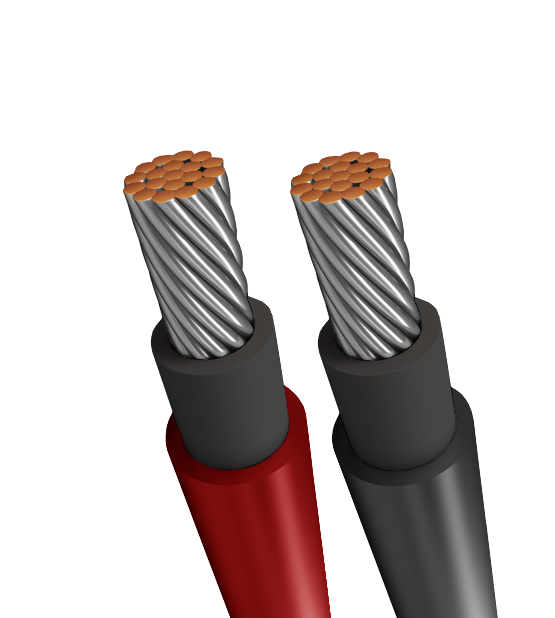

Solar Cable

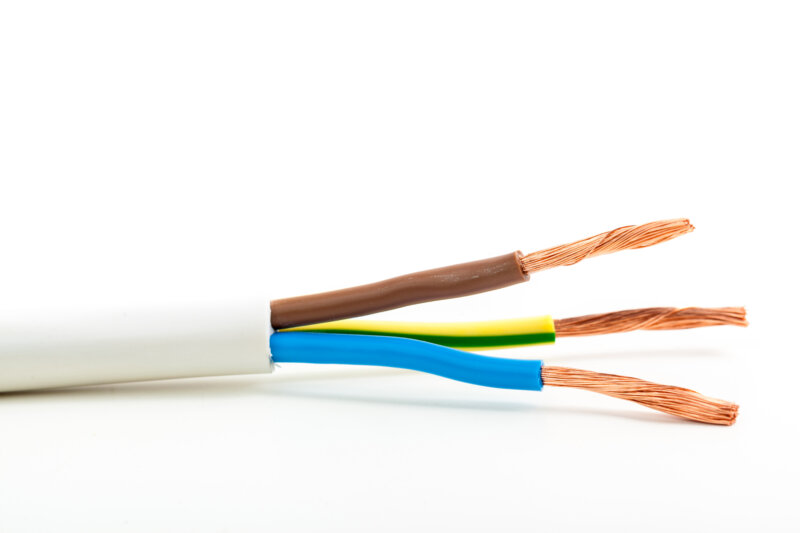

Normal Cable

Finally, that is electrical properties. Solar cables are not only designed to meet the general electrical requirements of power transmission but are tailored to the specific demands of solar power systems. These cables often feature low smoke, halogen-free properties, enhancing safety in the event of a fire. The unique electrical characteristics required in solar installations, such as low power loss and efficient power transmission, dictate the design and composition of solar cables. Normal cables, while versatile and suitable for a myriad of electrical applications, may lack the specific electrical properties optimized for solar power generation.

In conclusion, the differences between solar cables and normal cables are nuanced and purposeful. From insulation materials to temperature resistance, flexibility, durability, and electrical properties, each aspect of solar cables is meticulously engineered to meet the distinct challenges posed by solar power installations. While normal cables have their own set of applications and characteristics, they may not possess the specialized features necessary for the optimal performance and safety of solar power systems.