Flowserve Lubricated Plug Valves – Double Isolation

BRAND: Serck Audco

Based on Serck Audco Super-H pressure balanced taper plug technology, Double Isolation Plug Valve offers true bubble tight double block and bleed, within a single valve body.

Features and Benefits

Design Features

- Same face-to-face of a single valve.

- No pipework modification – total interchangeability with existing valves.

- Choice of bleed connection options.

- Same range as single valve including hard facing.

- Meets the same industry and fire-test standards as a single valve.

- Low life cycle cost – less than two single valves.

- Assured sealing on both sides of the valve.

- Reduced leak paths – eliminates inter-valve pipework on double block and bleed configurations.

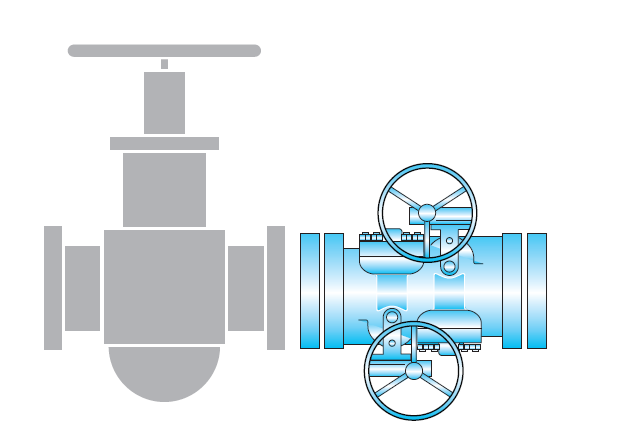

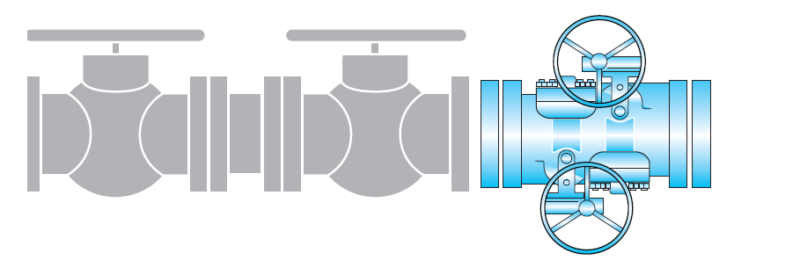

- Compact, lightweight alternative to gate valves and ball valves in series.

- Compared with Gate Valves: Same face-to-face but smaller overall & Compact design means less weight

- Compared with Ball Valves: One TIPV replaces two ball valves, Less interconnecting pipework means fewer leak paths, Weight saving, & Cost saving

Benefits

- Improved plant and personnel safety assured by a double isolation design that allows the operator to verify valve isolation before carrying out maintenance

- A cost-, space- and weight-saving alternative to a double block and bleed system using two valves in a series

- Ease of installation from a compact design with the same face-to-face dimensions as a single valve, often replacing it without the need for pipe work modifications

- Greater process control via a pressure balanced design that provides a true bubble-tight double isolation capability within a single valve body

Design Range

Standard

- API 6D – Specification for pipeline valves

- API 6A – Specification for wellhead equipment

- ISO 14313 – Petroleum and natural gas industries-Pipeline valves

- ISO 10423 – Petroleum and natural gas industries-Wellhead equipment

- API 599 – Metal plug valves – flanged, threaded and welding ends

- BS 5353 – Specification for steel plug valves

- ANSI B16.10 & BS 2080. – Face-to-face and end-to-end dimensions

Sample Applications

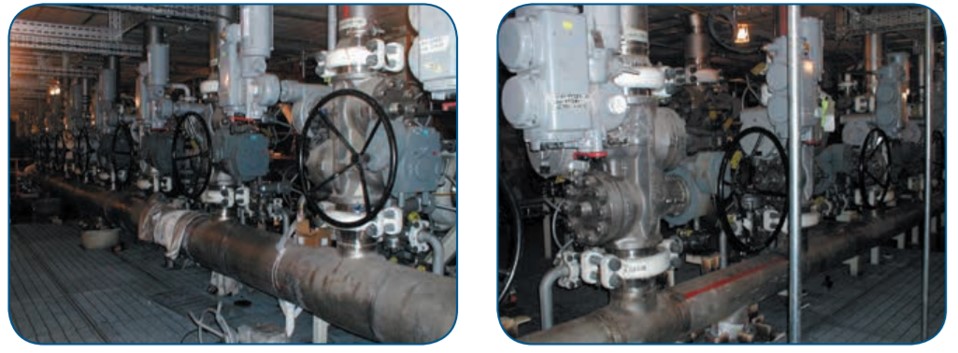

Typical Installations

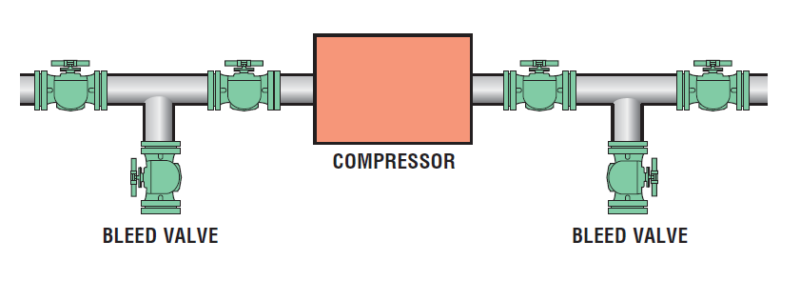

- Gas Transportation – Gas Compression Station

Configuration Using Ball Valves

Configuration Using Double Isolation Plug Valves

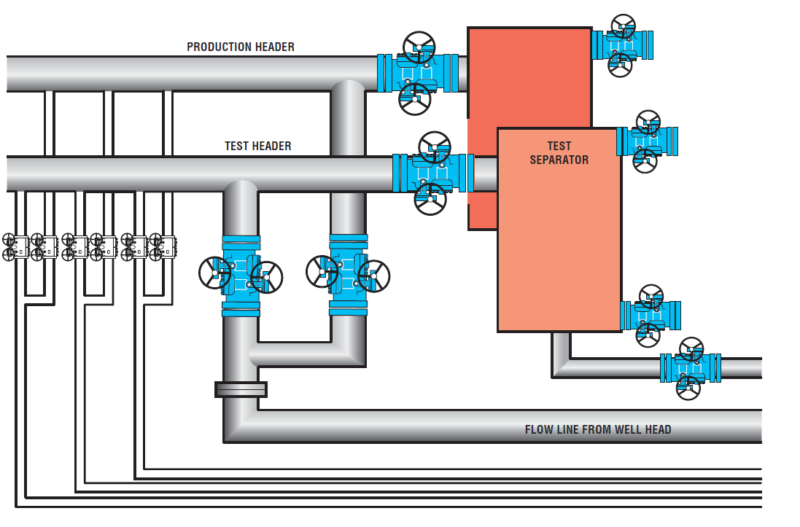

The valves illustrated are 8” class 1500 Double Isolation Plug Valves in 25% Cr. Duplex with hub ends. The valves are installed on a flowline header application. Morover, in this case one isolation is by electric actuator and the other isolation is by gear operator. Criteria for selection: true bubble tight isolation and space and weight saving over conventional ball or gate valves and minimum maintenance.

The valves illustrated are 8” class 1500 Double Isolation Plug Valves in 25% Cr. Duplex with hub ends. The valves are installed on a flowline header application. Morover, in this case one isolation is by electric actuator and the other isolation is by gear operator. Criteria for selection: true bubble tight isolation and space and weight saving over conventional ball or gate valves and minimum maintenance.

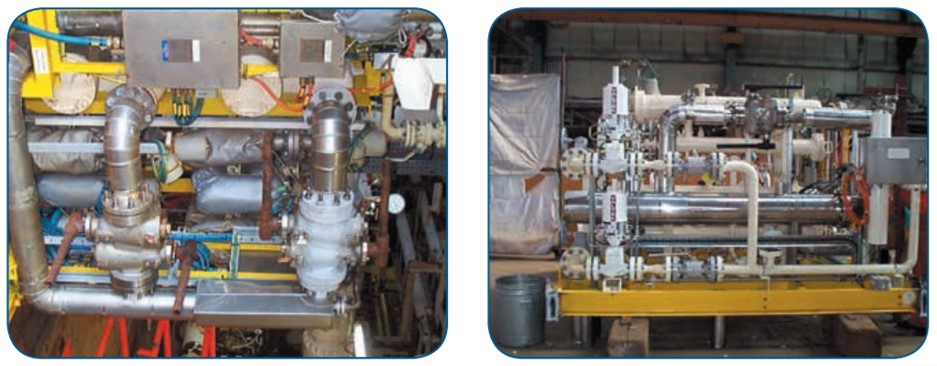

The valves illustrated are 4” class 300 flanged in Carbon Steel and Stainless Steel. The application is on a fuel skid and both plugs on each valve are lever operated. Criteria for selection: double block and bleed with true bubble tight isolation for reasons of safety, reliability and minimum maintenance.

The valves illustrated are 4” class 300 flanged in Carbon Steel and Stainless Steel. The application is on a fuel skid and both plugs on each valve are lever operated. Criteria for selection: double block and bleed with true bubble tight isolation for reasons of safety, reliability and minimum maintenance.

Reference