Grove Valves

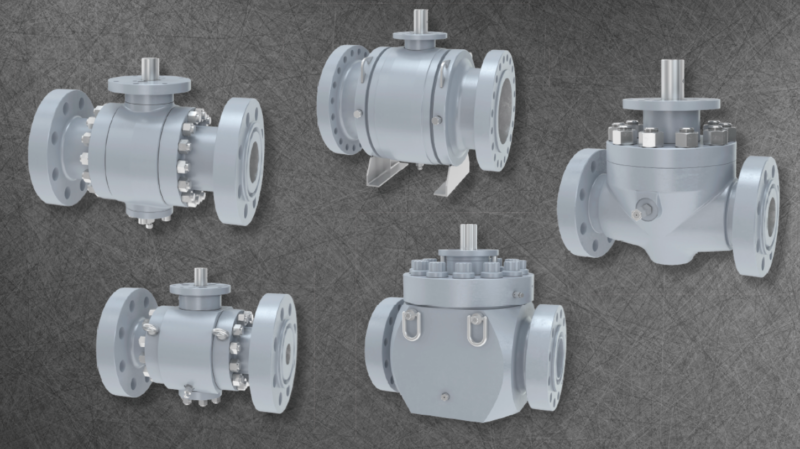

Grove Valves split-body side-entry ball valves are manufactured in a wide range of diameters and pressure classes, frequent-cycling, high- and low-temperature, corrosive demands of gas processing applications with increased safety and operational efficiency. Split-body construction allows the use of forged materials in various grades of carbon steel, stainless steel, and high alloys, equipping the valves for some of the most severe service conditions.

Application, Summary

Ball valve portfolio [ ¼ – 60 in and ANSI pressure class from150 to 2500]

The Cameron GROVE valve models include

- GROVE IST* integrated seat technology ball valves

- side-entry ball valve models B4, B5, B7, and B8

- top-entry BT valves.

Market segments and applications

- Onshore operations—separation, wastewater disposal, tank battery, recovery, SAGD, and oil sands applications

- Pipeline operations—transmission, emergency shutdown, pigging, and pump and compressor station applications

- Liquid tank storage—tank storage isolation, custody transfer, metering skids, and loading and unloading applications

- Offshore operations—production, separation, processing and compression, and storage, metering, and exporting

- Subsea operations—fluid control and isolation for manifolds, flowlines, and risers

Cameron is an authorized licensee to use the API monogram for specifications 6D and 6A. Our QMS program conforms to

- API Spec 6A

- API Spec 6D (license 001)

- API Spec 6DSS (license 003)

- API Spec Q1

- ATEX Directive 94/9/EC

- Canadian registration number

- EN 729-2—welding quality

- ISO 14001

- ISO 15848-1—fugitive emissions

- ISO 3834—quality of fusion welding of metallic materials

- ISO 9001

- OHSAS 18001—health and safety

- PED Directive 97 /23/EC

- SIL to IEC 61508—functional safety of electrical, electronic, and programmable electronic safety-related systems

How Grove Valves work

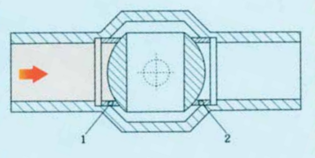

- Seat Seals

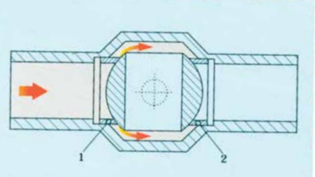

The GROVE seat design ensures double-barrier sealing in both directions (the normal self-relieving seats are a simple barrier of sealing). The sealing is performed by both a primary metal-to-metal seal and a secondary protected O-ring seal. - Double Piston Effect (DPE)

The DPE seat design was invented and patented by Cameron’s GROVE team. The DPE seat design allows for both seats to seal with pressure acting from the same side of the valve. In the event one seat becomes damaged, the user has the added advantage of the opposite seat sealing. By means of this double barrier, the sealing is ensured regardless of the direction of the flow through the valve.

If the upstream seat (1) becomes damaged and leaks, the pressure entering the body cavity acts on the downstream seat (2), sealing the downstream seat tightly against the ball.

GROVE split-body side-entry ball valves B4,B5,B7

Applications

GROVE split-body side-entry ball valves are manufactured in a wide range of diameters and pressure classes. In the standard versions, the valves are specified for transmission pipelines, pumping, compression and reinjection units, offshore platforms, onshore terminals, pig traps, measuring stations, and surge-relief skids. These valves also can be built for specialty applications, such as subsea installations and LNG plants. Split-body construction allows the use of forged materials in various grades of carbon steel, stainless steel, and high alloys, equipping the valves for some of the most severe service conditions.

- GROVE B4

Features

-

- Double-barrier stem seals (the upper seal can be replaced with the valves in-line, under pressure, with the ball in the closed position)

- Short coupled trunnions reduce unit bearing loads and operating torque

- Factory-positioned external stops

- Stem separated from the ball; anti-blowout design; side load on stem

- Plastic polymer insert for seat sealing

- Self-relieving seats for ASME Classes 150 and 300

- Metal-backed, self-lubricating PTFE sleeve bearing and thrust washers reduce torque and extend service life

- Nickel plating for trim parts

- Fire-safe graphite rings for protection against external leakage

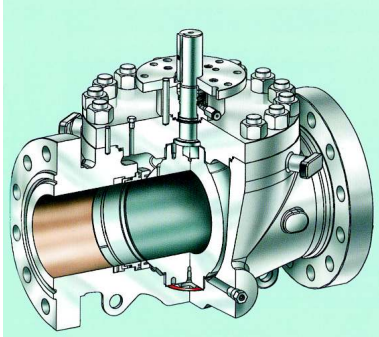

- The GROVE IST

The GROVE IST integrated seat technology ball valve meets and exceeds customer needs in critical applications—longer life span, small and lightweight footprint, high efficiency, and lower total cost of ownership.

The next evolution in trunnion-mounted ball valve design, the GROVE IST ball valve features a patented seat design that decouples ball flex and deformation from sealing performanceใ When pressure is applied to the valve, its integrated seat is energized, generating a reliable seal independent of ball deflection. While the valve is open, the patented spoiler in the counter seat diverts fluid and debris away from critical sealing areas, further increasing reliability The GROVE IST ball valve also features a top entry design for streamlined, simplified inline maintenance that reduces overall downtime

Features

-

- Optimized valve and compact actuator assembly that overcomes ball flexing and deformation up to 10,000 psi [68.9 MPa]

- Patented flow-diversion spoiler to protect primary sealing elements

- Enhanced sealing capability compared with conventional metal-seated ball valves

- Optimized design using finite-element analysis (FEA) and computational fluid dynamics (CFD)

- Pressure-balanced design for quick closing

- Top-entry body configuration with simplified inline maintenance

- Rigorous testing beyond industry requirements

Design standards

-

- API Specs. 6A and 6D

- American Society of Mechanical Engineers (ASME)

- Standard B16.34

- ASME Section VIII Div. I & II

- NACE MR0175/ISO 15156

- Design parameters

- Material configurations: carbon steel, low-alloy steel, and corrosion-resistant alloy

- Design temperature limits: –50 to 400 degF [–46 to 204 degC]

- Primary seal type: metal-to-metal

- Secondary seat seals: elastomer or thermoplastic options available

- Stem seals: elastomer or thermoplastic options available

For more information, Grove Valves

Certification and testing

- The valve was rigorously tested to internationally recognized standards for performance, sand slurry, and fire testing

APPLICATIONS The GROVE BT1 and BT2 valves are an advanced design of Top Entry ball valves, manufactured in a wide range of diameters and pressure classes.

Project Reference

| User | Location |

| PTTEP | PTTEP SIAM – Sirikit Oil field (S1) |

| PTTEP offshore G1 (Erawan, Platong, Stun, Funan) | |

| PTTEP offshore G2 (Arthit, Bongkot) | |

| PTTGSP | Sales Gas Valve |

| PTTOC | Gas Transmission Pipeline |

| Thapline | Lumlukka Tank farm |