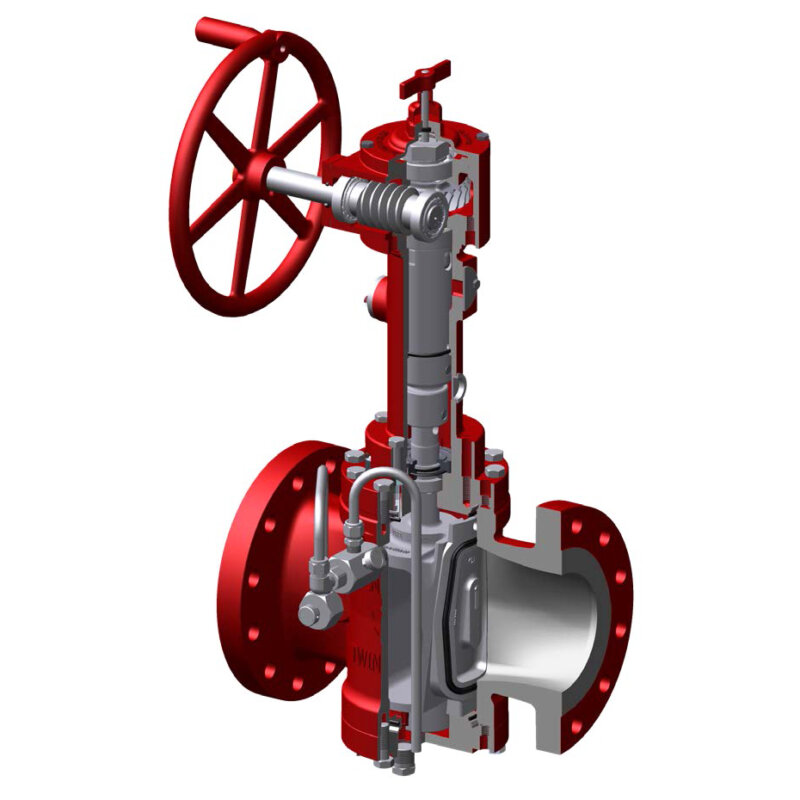

The focus is on the unprecedented General Twin Seal valve that has assisted in ensuring the implementation of rigid requirements of the double block-and-bleed valve service (hereafter: the DBB valve). The innovation of The General Twin Seal Plug Valve with double bleed function is one of the first versatile valves that offer unique features for exact and specific applications. The double bleed function in this valve is designed to provide additional safety and convenience in certain industrial processes.

Here are some main reasons why any industry, business, or individual needs to utilize the DBB valve technology in the General Twin Seal Plug Valve First and foremost, it’s the exceptional safety record and the overall safety factor that is always key and primary in every workplace action. In fact, the double bleed function allows for a more controlled release of pressure, thus ensuring a safer operation. This is especially important in processes where exact pressure control is crucial to prevent accidents or damage to equipment. The next factor is process control: The valve’s design with double bleed capability allows for better control over the flow of highly dangerous and volatile substances. This is beneficial in processes where maintaining specific pressure levels or preventing harmful over-pressurization is essential. The next key area is the maintenance of the valve. In fact, the double bleed feature can facilitate maintenance activities. It allows for depressurization and a necessary bleeding of the line before maintenance or repairs, reducing the risk of accidents and making the maintenance process more efficient and free of the past problematic areas where maintenance is concerned. The safety and management of repairs are more efficient and expeditious. The last but not least factor is the incredible versatility of the General Twin Seal Plug Valves. The DBB valves are known for their durability, reliability and versatility. In addition to the innovation of a double bleed function, this DBB valve adapts and is suitable for a wider range of applications, providing added flexibility in various complex and complicated industrial processes. Moreover, the DBB valve possesses a non-lubricating, resilient seal and expanding plug-type valve that has a mechanical process that allows for the rotation of the open and closed position. Most importantly, the plug and seal rotates freely with no human contact necessary which eliminates seal abrasion and increases durability.

First, a detailed explanation of the four specific reasons for the double bleed function are the following. The first is it must follow the API 6D which stipulates that all DBB valves must relieve pressure in liquid service. The second is to relieve excess body pressure due to thermal expansion. The third is to consistently verify the seal integrity. The fourth and final reason is to ensure when valves are filled with a certain temperature requirement. For instance, a normal daily 30 F swing in ambient temperature may increase the pressure on the body cavity up to 2250 psi. The DBB valve controls the abhorrent effects of the swings in both temperature and pressure.

The cutting-edge valve is a general Twin Seal double block-and-bleed plug valve that is a specific type of plug valve that serves various functions in industrial applications. Specifically, this valve is a high-integrity, positive shutoff valve. They are versatile and used for both inline testing and field maintenance.

The six main applications of the DBB valve are the following:

- pipeline pumping stations and terminals

- refinery bulk loading terminals

- aviation and naval fueling systems

- crude oil and refined products metering and measurement systems

- pig launcher and receiver systems

- other specialized applications in industrial process plants

Specific Design Advantages :

The DBB valve has some key features that ensure the quality and necessity of the innovation. The first is the Bubble-Tight Seal which is a Twin Seal design to guarantee a bubble-tight seal that prevents any spontaneous leaking of fluids. The highest quality Twin Seal is key to the process of maintaining a tight seal.

The next key function is the Bi-Directional Sealing which is designed to ensure an efficacious sealing in both flow directions. Thus, increasing its essential versatility and utilization in the differing variety of pipeline configurations. The next key feature is the Low Operating Torque; the DBB valve is specifically engineered to make it expeditiously and with ease open and close. This feature makes it more efficient for DBB valve operations.

What is the DBB valve made from? The valve is a Durable Construction with stainless steel and other corrosion-resistant alloys for obvious benefits in environmentally destructive industrial settings. Therefore, the durability of the DBB extends the reliability and longevity of various operating conditions. Another key feature is the Reduced Maintenance Requirements. The specific design of the DBB valve minimizes the need for frequent repairs. The DBB is highly advantageous for industries where maintenance and downtime expenses are regular concerns. The next feature is the Versatility of Applications. The DBB valve can be utilized in a wide variety of industrial applications that include the extraction of fossil fuels, the petrochemical industry, the chemical processing industry, and many other uses. The versatility of the DBB valve makes them conducive for the many fluid-handling processes. Another feature is the Quick Opening and Closing of the DBB valve. The design allows for an expeditious opening and closing; and facilitates the increased efficiency of control in the actual flow of fluid. This is highly advantageous when rapid response times are necessary. The next key feature is the Ease of Automation. The DBB valves can be automated with ease for obvious remote and computerized; digital control. Once again, this has increased the variety of utilization in automated industrial environments and systems. The last but not least feature is the High Pressure and Temperature Capabilities which depend on the specific model and materials utilized. The DBB valve can be used in high-temperature and high-pressure applications making them ideal for demanding industrial protocol and harsh workplace environments.

Finally, the proper and in-depth understanding of the features and functions of the DBB valve can help in choosing the right valve for specific applications, ensuring efficient and reliable fluid control in various industrial settings.