For over 85 years, Grove valves have been synonymous with innovation, reliability, and performance in the world of flow control. From their humble beginnings in 1934 as the Grove Regulator Company to their current position as a leading brand under Schlumberger, Grove Valves have consistently set the standard for quality and dependability in various industries. Due to their reliability and efficient control of fluid flow, Grove valves have become a crucial component in various industries.

Understanding Grove Valve

Grove valves are industrial valves that play a pivotal role in controlling the flow of liquids or gases within a system. These valves are engineered with precision to ensure optimal performance in demanding conditions.

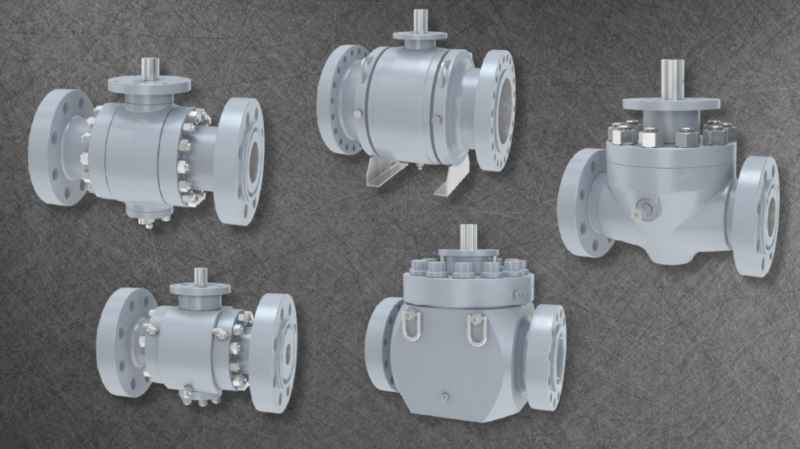

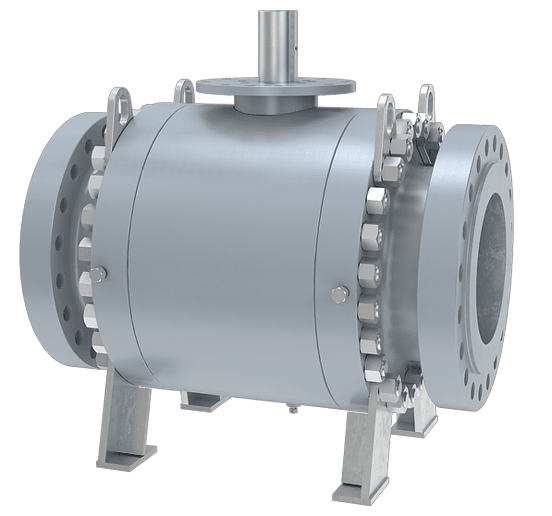

Grove valves, like many other types of industrial valves, operate on the principle of controlling the flow of fluids, such as liquids or gases, within a system. The specific design and functionality of Grove valves may vary based on their intended application and the type of valve within the Grove valve family. Grove valves encompass various types, including gate valves, ball valves, and butterfly valves. Each type has a distinct mechanism for controlling the flow of fluids.

In the case of gate valves, which are commonly used in many industrial applications, the valve has a gate or wedge-shaped disc that can be raised or lowered within the valve body. When the gate is lifted, it allows fluid to flow through the valve, and when lowered, it obstructs the flow.

Ball valves, another common type, use a spherical disc (the ball) inside the valve. When the valve is open, the ball allows fluid to pass through, and when closed, the ball is rotated to block the flow.

Butterfly valves feature a disk-shaped element, known as the butterfly, which can be rotated to control the flow. When the valve is open, the disk is parallel to the flow, and when closed, it is perpendicular, obstructing the flow.

Basic Working Mechanism of Grove Valves

Irrespective of the specific type, grove valves generally operate based on the following principles:

Opening and Closing: At the core of Grove valves’ functionality lies the ability to open and close to control fluid flow. The opening and closing mechanisms vary based on the valve type. In gate valves, the gate is raised or lowered to allow or block the flow. Ball valves rotate the ball to open or close the passage, while butterfly valves pivot the disk to modulate fluid flow.

Actuation for Precision : Grove valves can be manually operated or actuated using external power sources for enhanced precision and automation. Manual operation involves turning a handle or lever, giving operators direct control. Actuated valves, on the other hand, utilize electric motors, pneumatic actuators, or hydraulic systems for remote and automated operation. This ensures that valves can be precisely adjusted to meet the demands of complex industrial processes.

Sealing for Security : A critical aspect of Grove valves’ operation is the establishment of a secure seal when closed. This prevents any unintended leakage of fluids. The sealing mechanism often involves the use of gaskets, O-rings, or other sealing materials, ensuring a tight closure and maintaining the integrity of the system.

Flow Control: Grove valves provide precise control over the rate of fluid flow. This is essential for regulating processes and ensuring optimal performance in various industrial applications.

Materials Used in Grove Valves

Grove valves are typically crafted from high-quality materials to withstand the rigors of industrial environments. Common materials used in their construction include stainless steel, carbon steel, and other alloys known for their corrosion resistance and durability. This robust construction ensures longevity and reliability, even in challenging operating conditions.

Industries Using Grove Valves

Grove valves find applications across a wide range of industries, owing to their versatility and performance. Some of the key sectors that extensively use grove valves include:

Oil & Gas : From upstream exploration to downstream processing, Grove valves handle the flow of oil, gas, and other hydrocarbons with safety and efficiency. Their high-pressure capabilities make them ideal for pipelines and wellheads.

Power Generation : Grove valves play a vital role in power plants, regulating the flow of water, steam, and other fluids crucial for power generation. Their durability and reliability ensure uninterrupted operation and efficient energy production.

Water & Wastewater Treatment : Grove valves are essential for controlling water flow in treatment plants, ensuring clean water delivery and proper wastewater disposal. Their corrosion-resistant materials and innovative designs make them ideal for harsh water environments.

Chemical Processing : Grove valves handle the flow of various chemicals in the chemical industry, ensuring safety and containment. Their leak-proof designs and diverse material options cater to specific chemical compatibility needs.

Advantages of Grove Valves

Grove valves offer a variety of advantages, as follows:

Reliability : Grove valves are known for their reliability and consistent performance, even in harsh conditions. This reliability is crucial for maintaining the integrity of industrial processes.

Durability : The use of high-quality materials in the construction of Grove valves ensures durability and longevity, reducing the need for frequent replacements and maintenance.

Precision Control : These valves are designed for precise control of fluid flow, allowing for accurate adjustments and enhanced efficiency in various industrial applications.

Versatility : Grove valves are versatile and can be adapted to different applications and industries, making them a preferred choice for engineers and operators facing diverse operational requirements.

In conclusion

Grove valves play a crucial role in controlling liquids and gases in industries. Their diverse types and robust mechanisms enable them to navigate the complexities of different industries, from energy production to chemical processing. As we demystify the workings of Grove valves, it becomes clear that these valves are not just components; they are precision instruments, finely tuned to orchestrate the symphony of fluids in the industrial landscape. Grove valves continue to evolve, embracing new technologies and adapting to the changing needs of the industry. The focus on research and development keeps Grove valves modern and important for controlling flow. With a focus on sustainability and environmental responsibility, Grove valves are paving the way for a cleaner and more efficient future.