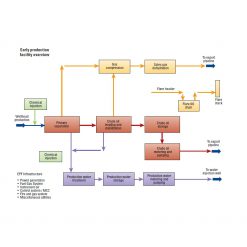

Overview – BFCC Copper Chlorine System

-

Tested, environmentally gentle process to prevent biofouling of water systems

With more than 25 years of proven reliability and over 160 units operating worldwide in a wide variety of applications, the BFCC system is smaller and less expensive than other units available on the market—even in comparison with conventional sodium hypochlorite generators—and requires much less power and maintenance.

-

Lower environmental impact from a field proven system

The BFCC copper chlorine system generates small but preciseconcentrations of copper and chlorine with DC electrolysis. These concentrations discourage system contamination while minimizing environmental impacts. The system has no moving parts, and there is no requirement for a hydrogen disengagement system, whichfurther reduces environmental effects and operating costs. The simplicity of the design offers a small footprint, lower maintenance, and greater system design flexibility.

-

Efficient DC electrolysis reduces capex and opex

The BFCC system uses DC electrolysis to produce copper and chlorine at low concentrations—typically 5 ppb and 50 ppb, respectively—considerably less than a chlorine-only system. These low concentrations have a significantly lower environmental impact and can be generated with a simpler, smaller system with less ongoing input requirements. Additional cost-saving attributes include:

- Proven lower copper and chlorine dosing rates versus copper aluminum or chlorine dosing alone, enable a smaller cell design and also require a smaller power unit, which reduces power and space requirements.

- Lower chlorine injection rate reduces corrosion caused by chlorine, reducing opex. Smaller, stand-alone units do not require hydrogen disengagement tanks, further reducing the footprint and lowering capex.

- The simple, zero-moving part cell design increases run times and improves protection of other seawater treatment equipment, reducing opex.

- The patented Sequence Target Dosing system increases the reliability of the dosing system through a reduction in cell fouling, reducing opex.

Application of BFCC Copper Chlorine System

Based on Faraday’s laws, the unit employs a constant-current, variable-voltage DC power supply to energize copper and chlorine producing electrodes. The low concentrations (5-ppb copper and 50-ppb chlorine) generated are then added into the system and work together to keep the water system free of both micro-and macrofouling. The equipment is smaller and less expensive compared withconventional units and sodium hypochlorite generators while requiring much less power and maintenance.

![BFCC_Copper_Chlorine_System[1] Copper-Chlorine-System](https://www.gmsthailand.com/wp-content/uploads/2021/09/Copper-Chlorine-System.jpg)