Overview – CYCLOTECH WDC Series Wellhead desanding cyclone technologies

Customized new-generation solids separation technology

Schlumberger wellhead and production desanding cyclones represent a new generation of solids separation technology specifically designed for multiphase wellstreams. These custom-engineered technologies use the presence of the gas phase to improve rather than detract from separation performance.Therefore, CYCLOTECH WDC Series Wellhead desanding cyclone has an important role in this part.

Advantages

- Improved reliability through protecting chokes, flow lines, and manifolds from erosion as well as downstream equipment from erosion, corrosion, and blockage

- Reduced production separator sand jetting requirements

- Increased production above sand‑free rates

Application of CYCLOTECH WDC Series Wellhead desanding cyclone technologies

WDC Series technologies have no moving parts and separate solids from multiphase well streams by density differential, using only a small pressure drop across the cyclone. A solids-laden multiphase flow is directed into the inlet section of the cyclone via a tangential inlet port. This causes the fluid to spin at high velocity, creating a high-g radial acceleration field. The dense-phase solid particles are forced outward to the hydrocyclone inner wall. There, through internal hydrodynamic forces, solids are ejected from the apex of the cyclone while the rest of the multiphase flow exits via an axial port that is adjacent to the inlet. The separated solids are collected in a separate solids accumulator, which can be periodically purged on line without interrupting the hydrocyclone operation. This eliminates the need for duty or standby operation.

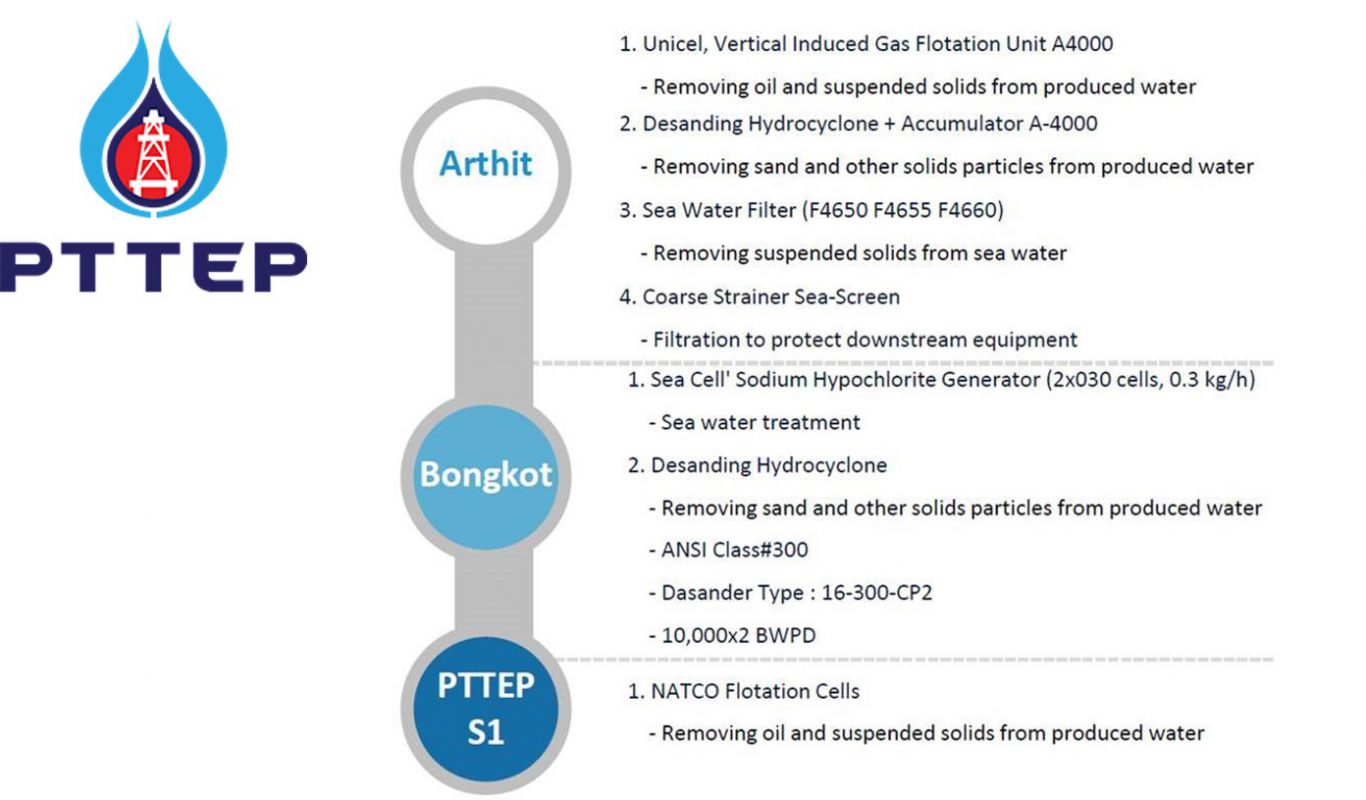

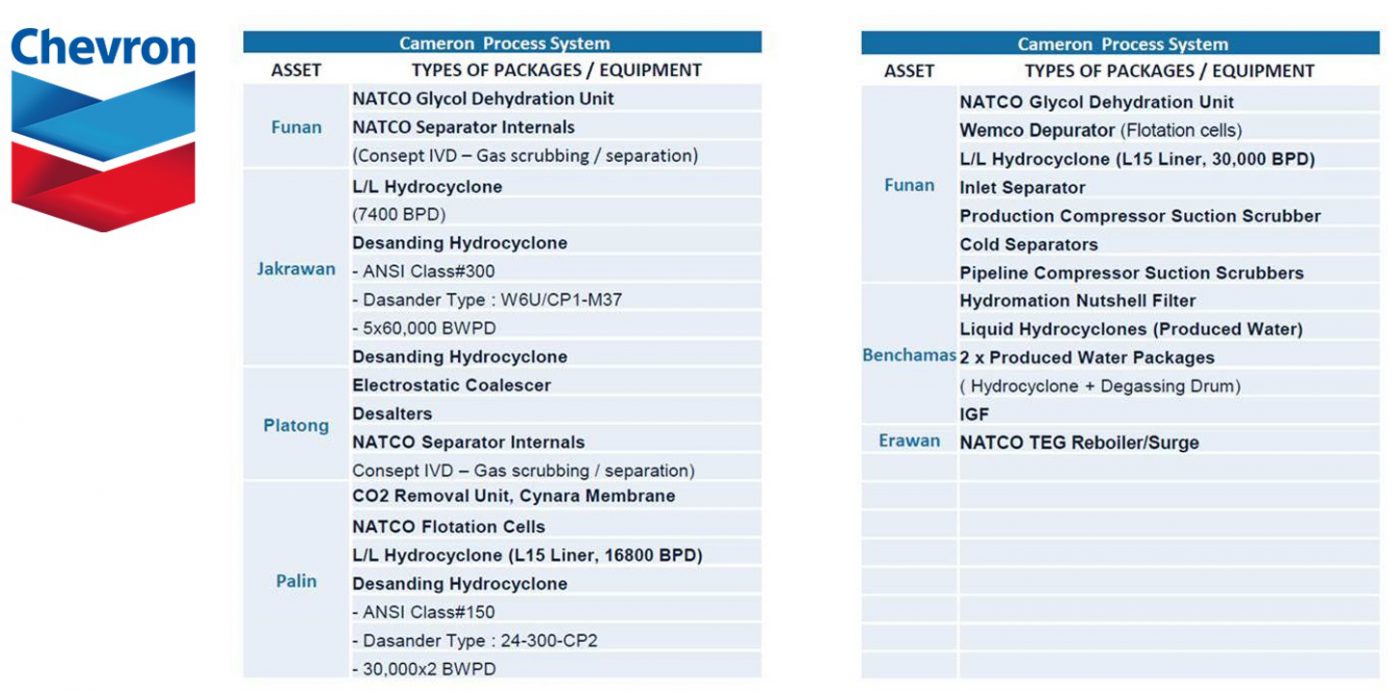

Project Reference

Brochure

Download