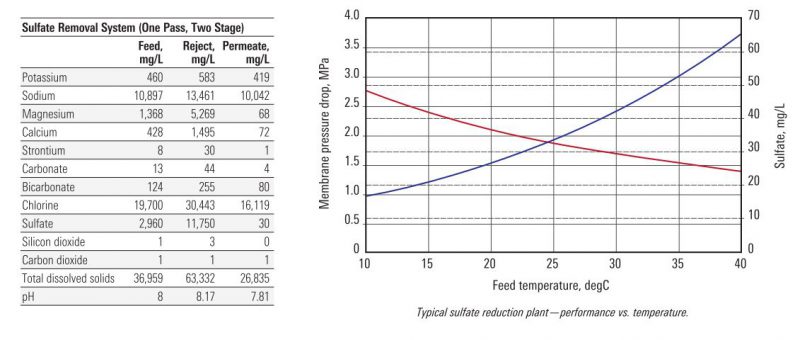

Overview – Sulfate Removal System

Prevent reservoir damage from sulfate introduction

There are two main problems that the sulfate removal system can solve. One is scale control and the other one is souring control. When sulfates run into the reservoir, the scale will be precipitated. After that, it will react with barium and strontium salts which are already in the formation.

Removing sulfate can reduce feed for existing sulfate-reducing bacteria in the formation. Hydrogen sulfide is the byproduct of bacteria’ s consumption.To avoid damaging operation and corrosion, hydrogen sulfide (H2S) should be removed because it will decrease lifespan of the equipment.

Incorporate sulfate removal into a seawater process

After spending many years for deep understanding and experience of design and installation ,sulfate removal system has advantages beyond scales or hydrogen sulfide reduction.The removal system can be used with other technologies that we provide, such as the Polymem UF seawater ultrafiltration system. The entire process guarantee is also available rather than a guarantee for individual technologies.

ADVANTAGES

- High-quality injection water

- Avoidance of well workover

- Reduced HSE hazards

- Reduced need for biocides

- Reduced scaling in piping and equipment

- More effective squeeze treatments

- Control of bacterial well souring

- Lower operating costs

- Increased productivity

Application of Sulfate Removal System

To help solve problems from the source, sulfate removal technology is one of the advanced technologies to enable productivity and lower costs. Before injection, removing sulfate can decrease barium and strontium sulfate scaling and prevent reservoir souring.

Since intending to solve problems sustainably, Schlumberger enhances membrane separation solutions for sulfate removal. Schlumberger develops not only stand-alone but also turnkey systems for any customer’s requirements. Therefore, these solutions provide efficient technologies for

- vertical production wells

- gravel-pack wells

- dilution water in HPHT environments

- horizontal wells with subsea tiebacks

- floating production systems

- reservoir souring control.

One of sulfate reduction methods is Membrane separation. Plus, this method is very environmentally friendly. The low-sulfate seawater product is normally in the range of 40 mg/L and dependent on water temperature and other operating parameters. The percentage of product from feedwater is 75%.

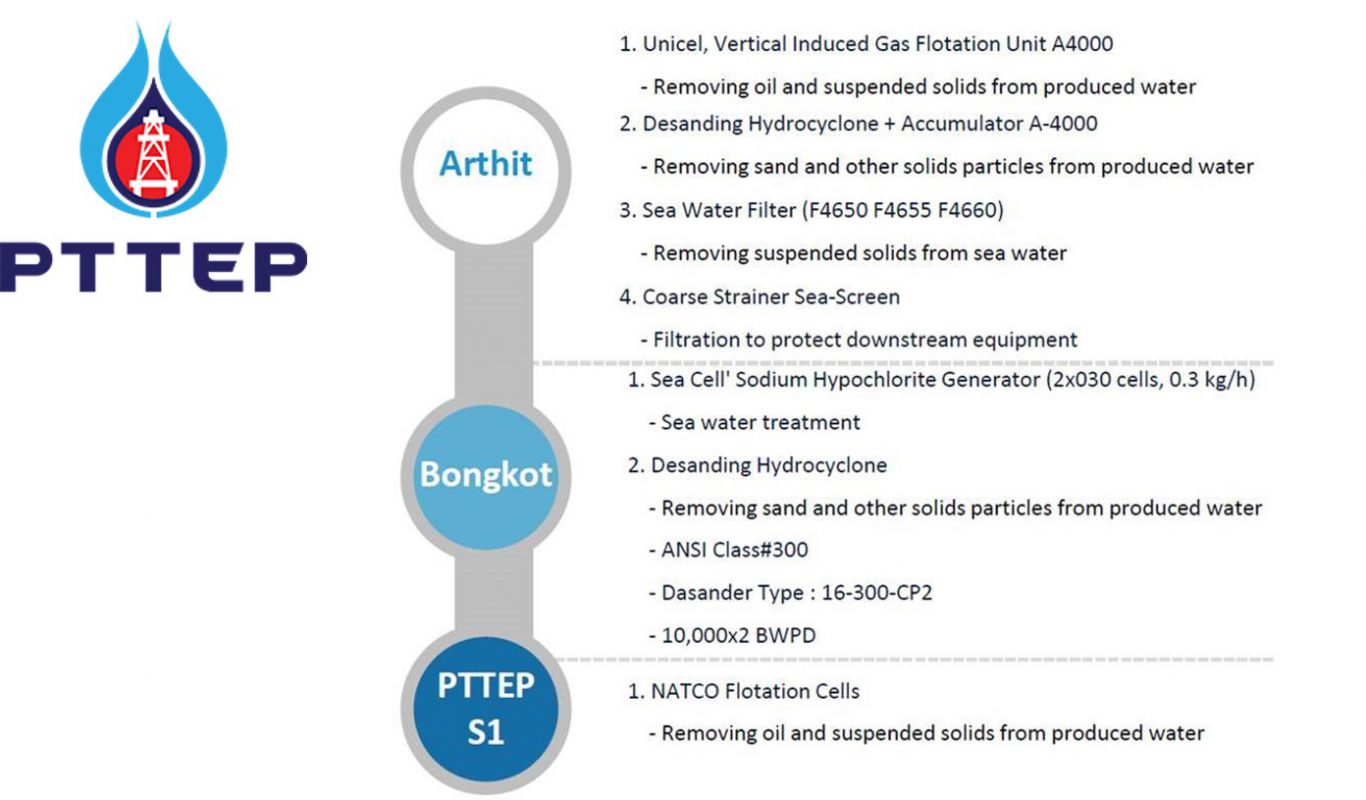

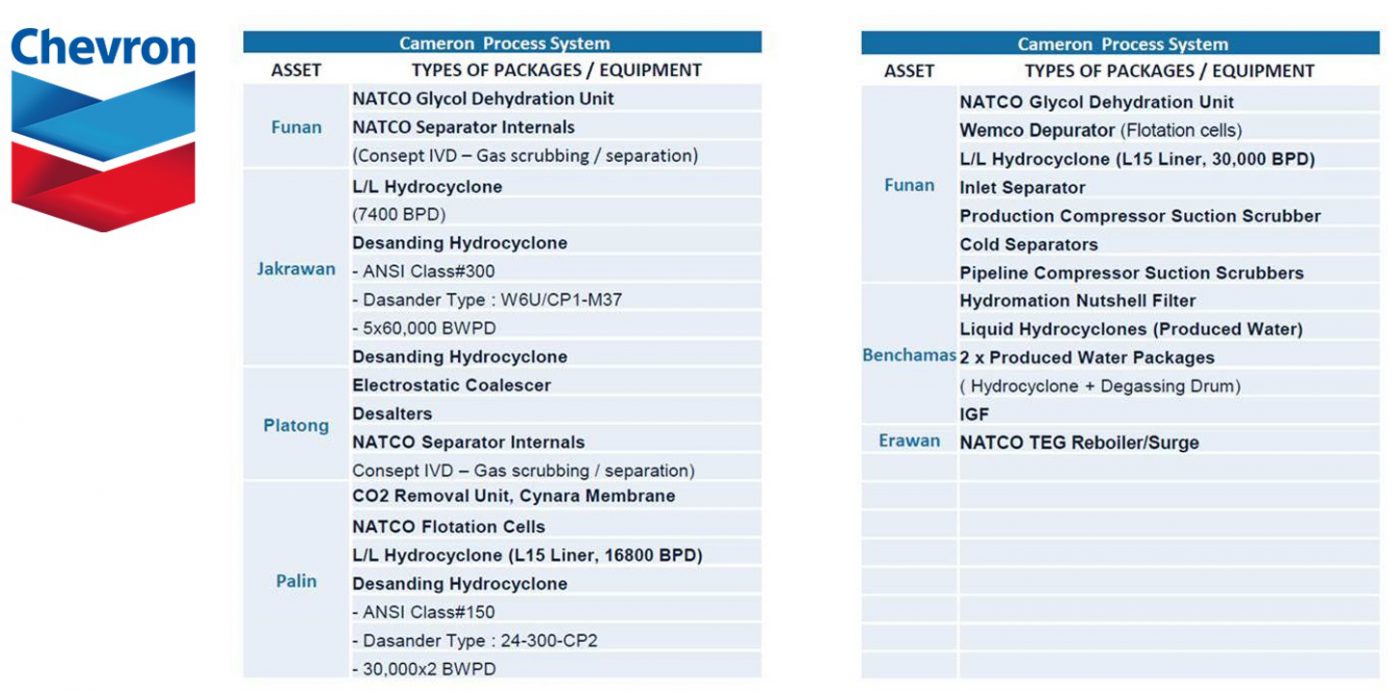

Project Reference

Brochure

Download